© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 347

Chapter 5

PolyLEVEL

®

Polyurethane Foam and Resin

APPENDIX 5A

TECHNICAL INFORMATION

PolyLEVEL

®

400

Technical Information

Description

PolyLEVEL

®

400 is a two-component, water

blown, nominal 4 pcf density, polyurethane

foam system designed for concrete slab raising,

under-slab void fill and cavity fill applications.

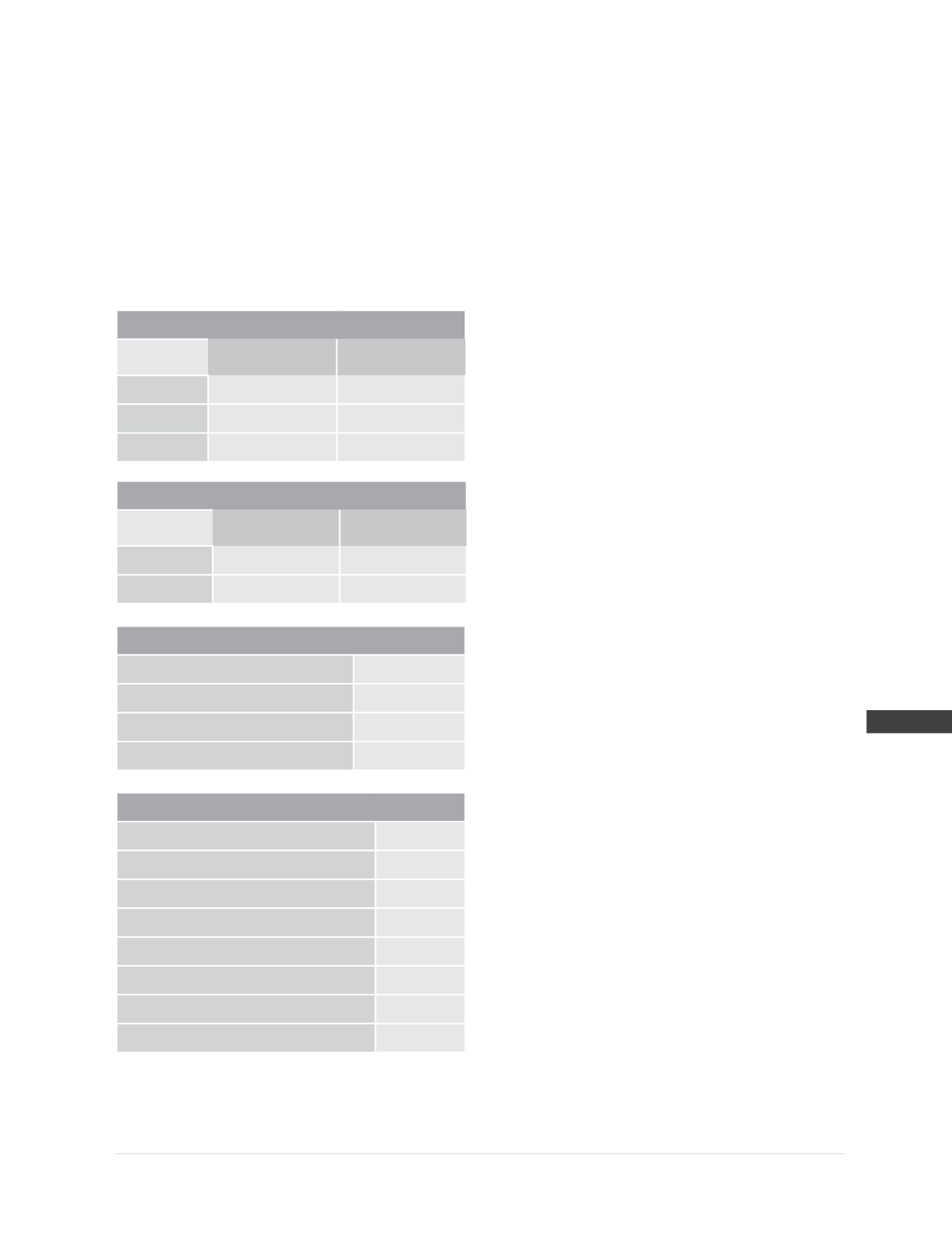

Typical Resin Properties

PolyLEVEL

®

400 R PolyLEVEL

®

400 A

Viscosity

(1)

700 cps

200 cps

Unit Weight

9.4 lb/gal

10.25 lb/gal.

Shelf Life

6 months

6 months

Mix Ratio

PolyLEVEL

®

400 R PolyLEVEL

®

400 A

By Weight

100 parts

109 parts

By Volume

100 parts

100 parts

Typical Reaction Properties

Cream Time

(1)

25 sec

Rise Time

(1)

90 sec

Density

(2)

4 pcf

Typical Compressive Strength

(2)

60 psi

Typical Physical Properties

(3)

Typical In-Place Density

(ASTM D1622)

6.5 pcf

Compressive Strength

(ASTM D1621)

100 psi

Shear Strength

(ASTM C273)

140 psi

Closed Cell Content

>90%

Water Absorption

(ASTM D2842)

<0.02 lb/sq ft

Resistance to Solvents

Excellent

Resistance to Mold and Mildew

Excellent

Maximum Service Temp

200°F

(1)

At 77°F

(2)

FRC = Free Rise Condition

(3)

Average value from laboratory testing and should serve only as

a guideline.

Storage and Cleanup

Shelf life is 6 months, in original, unopened

factory containers, under normal storage

conditions of 55° to 85° F. Do not store in direct

sunlight. Keep drums tightly closed when not in

use. Cured product may be disposed of without

restriction. Excess liquid ‘A’ and ‘R’ material

should be mixed together and allowed to cure,

then disposed of in the normal manner.

Safe Handling of Liquid Components

Use caution in removing caps and bungs from the

container. Loosen caps and bungs first to let any

built up gas escape before completely removing.

Avoid prolonged breathing of vapors. In case of

chemical contact with eyes, flush with water for

at least 15 minutes and get medical attention.

For further information refer to “MDI-Based

Polyurethane Foam Systems: Guidelines for

Safe Handling and Disposal” publication AX-119

published by the Center for the Polyurethanes

Industry 1300 Wilson Blvd, Suite 800, Arlington,

VA 22209.

Caution

Polyurethane products manufactured or

produced from this liquid system may present a

serious fire hazard if improperly used or allowed

to remain exposed or unprotected. The character

and magnitude of any such hazard will depend

on a broad range of factors which are controlled

and influenced by the manufacturing and

production process, by the mode of application

or installation and by the function and usage

of the particular product.

Any flammability

rating or reference contained in this or other

PolyLEVEL

®

400 literature is not intended

to reflect hazards presented by this or any

other material under actual fire conditions.

These ratings are used solely to measure and