© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 267

APPENDIX 3B

DRIVE STAND SPECIFICATIONS

Chapter 3

Hydraulically-Driven Push Piers

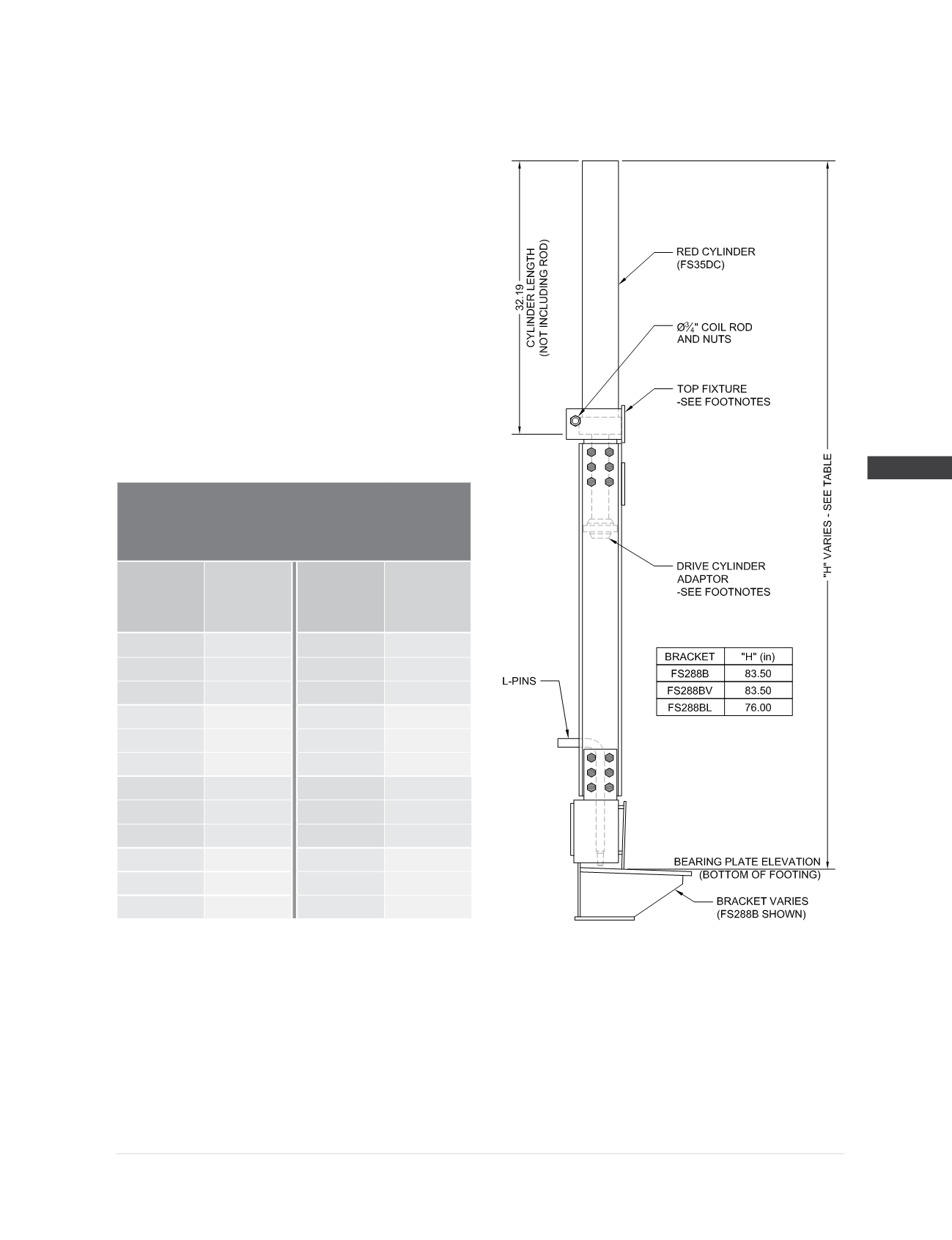

Model 288 Drive Stand Specifications

when used with the RED

(5)

Drive Cylinder (FS35DC)

Compatible Brackets

(3)

:

FS288B, FS288BV,

FS288BL, FS288BFM

Drive Cylinder

(5)

(FS35DC):

Stroke = 22”

Cylinder action = double

Bore =

Ø

3.50”

Hydraulic area = 9.62 in

2

Max operating pressure

(2)

= 8,000 psi

Drive Cylinder Adaptor

(4)

:

FSDCA (reversible)

Drive Stand Hardware

(1)

:

(1) -

Ø

3/4

” x 12” long coil rod with nuts

(2) -

Ø

1” x 15” long L-pins

Drive Stand Rated Drive Load

(2,3)

60.0 kips

Hydraulic

Pressure

(psi)

Drive

Force

(2,3)

(kips)

Hydraulic

Pressure

(psi)

Drive

Force

(2,3)

(kips)

400

3.8

4,200

40.4

800

7.7

4,400

42.3

1,200

11.5

4,600

44.3

1,600

15.4

4,800

46.2

2,000

19.2

5,000

48.1

2,400

23.1

5,200

50.0

2,800

26.9

5,400

52.0

3,200

30.8

5,600

53.9

3,400

32.7

5,800

55.8

3,600

34.6

6,000

57.7

3,800

36.6

6,200

59.7

4,000

38.5

6,235

60.0

(1)

Drive stand should never be operated without all hardware components firmly in place.

(2)

Do not operate at pressures that produce drive forces in excess of the drive stand’s rated drive load. Max operating pressure of the drive

cylinder produces forces that exceed this value and is given for informational purposes only.

(3)

Do not operate at pressures that produce drive forces in excess of the “maximum drive force during installation” values specified for the

bracket being installed (see Bracket Specifications and Capacities).

(4)

Drive cylinder adaptor FSDCA is a reversible adaptor that is compatible with both PP288 and PP350 push pier systems. Assemble the

adaptor to the cylinder rod in the appropriate orientation for the corresponding pier size being installed.

(5)

Note that the mounting flange dimensions are different between the RED and GRAY cylinders (FS35DC and FS425DC) and thereby require

the use of unique top fixture weldments that correspond to the appropriate drive cylinder.