© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 274

APPENDIX 3C

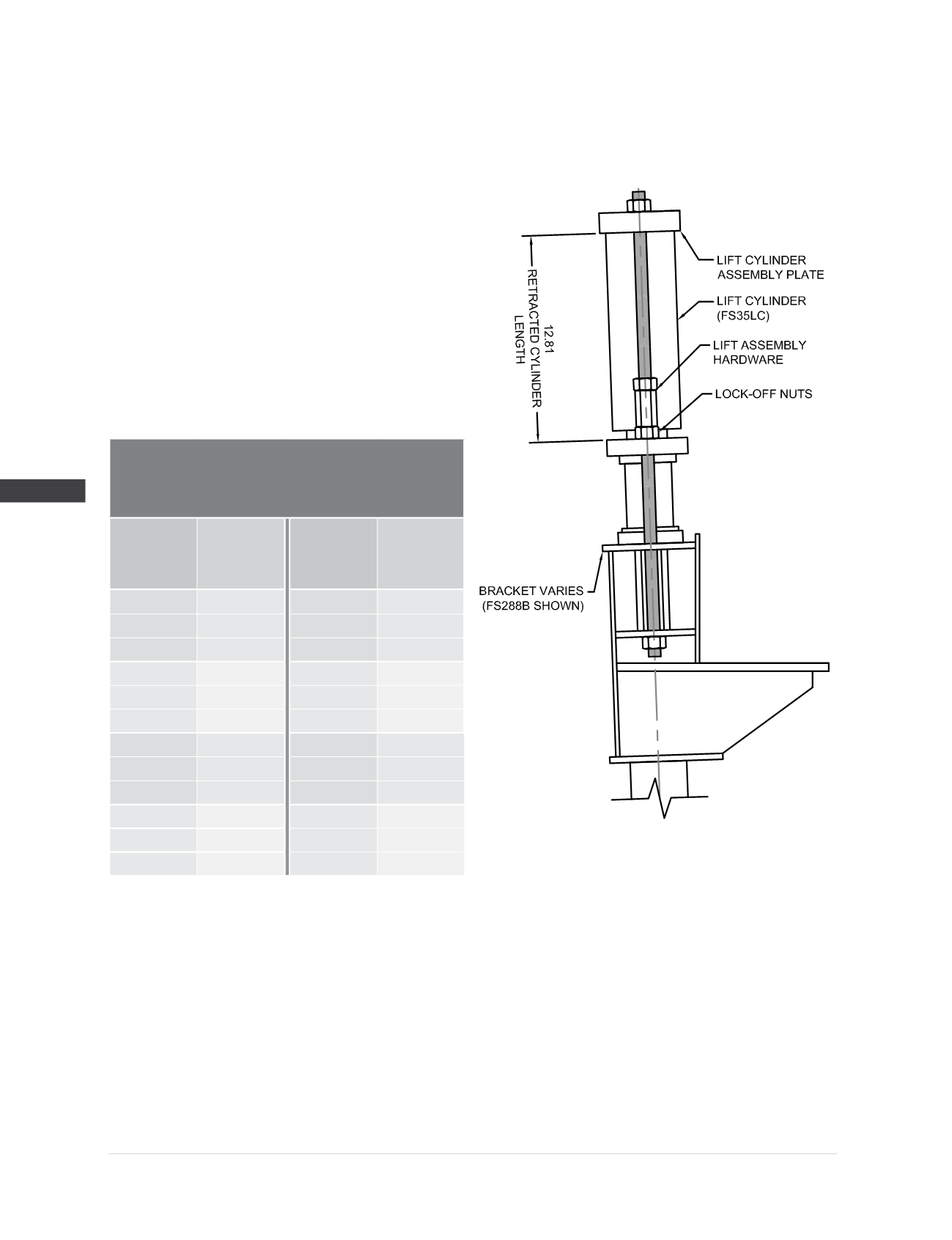

LIFT ASSEMBLY SPECIFICATIONS

Chapter 3

Hydraulically-Driven Push Piers

Model 288 Lift Assembly

(2)

Specifications

Compatible Brackets

(4)

:

HP238B2, HP288B2, FS288B

FS288BV, FS288BL, FS288BFM

Lift Cylinder (FS35LC):

Stroke = 4”

Cylinder action = double

Bore =

Ø

3.50”

Hydraulic area = 9.62 in

2

Max operating pressure

(3)

= 8,000 psi

Lift Assembly Hardware

(1,2)

:

(2) -

Ø

3/4

” x 16” long all-thread rod

with nuts and hex couplers, or

(2) -

Ø

3/4

” x 16” long coil rod

with nuts and hex couplers

Lift Assembly

Rated Lifting Load

(3,4)

39.7 kips

Hydraulic

Pressure

(psi)

Lift

Force

(3,4)

(kips)

Hydraulic

Pressure

(psi)

Lift

Force

(3,4)

(kips)

200

1.9

2,600

25.0

400

3.8

2,800

26.9

600

5.8

3,000

28.9

800

7.7

3,200

30.8

1,000

9.6

3,400

32.7

1,200

11.5

3,600

34.6

1,400

13.5

3,700

35.6

1,600

15.4

3,800

36.6

1,800

17.3

3,900

37.5

2,000

19.2

4,000

38.5

2,200

21.2

4,100

39.4

2,400

23.1

4,130

39.7

(1) Hardware used in the lift assembly must be selected to match the hardware used with the installed bracket assembly.

(2)

Note that the only difference between the model 288 and model 350 lift assemblies is the diameter of the threaded rod hardware. All other

components of the two assemblies are identical.

(3)

Do not operate at pressures that produce lift forces in excess of the lift assembly’s rated lifting load. Max operating pressure of the lift

cylinder produces forces that exceed this value and is given for informational purposes only.

(4)

Rated lifting load is given for the lift assembly only. Do not operate at pressures that exceed the allowable capacities of the system which are

governed by the allowable capacities of the bracket and other system components, as well as the torque correlated soil capacity, or installed

driving force divided by an appropriate factor of safety. All of these governing limits are outlined in places elsewhere in this appendix.