© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 317

APPENDIX 4B

POWERBRACE™ SYSTEM

Chapter 4

Miscellaneous Structural Support Products

PowerBrace

™

System

Technical Specifications & Spacing Guidelines

Steel Beam:

S4x7.7 ASTM A572 Grade 50 with length of 8 or 9 feet.

Top Bracket Assembly:

3/8

” ASTM A36 L-shaped bent plate 3.50” x 3.50” x 5” long

with holes for bracket hardware field cut to length.

2.50” long ASTM A36 bent plate beam capture

(1) -

Ø

1” x 5” long ASTM A307 bolt with nut

(2) -

Ø

3/4

” x 3” long ASTM A307 bolts with nuts and washers

Top assembly also available as a larger bracket with 4 bolts instead of 2.

Bottom Bracket Assembly:

1

” ASTM A36 L-shaped bent plate 2.50” x 1.75” x 5.50” long

with holes for bracket hardware.

(2) -

Ø

3/4

” Red Head Dynabolt sleeve anchor with effective length = 2.50”

Surface Finish:

All components of the bracket assemblies and the steel beam are electrozinc plated per ASTM B633.

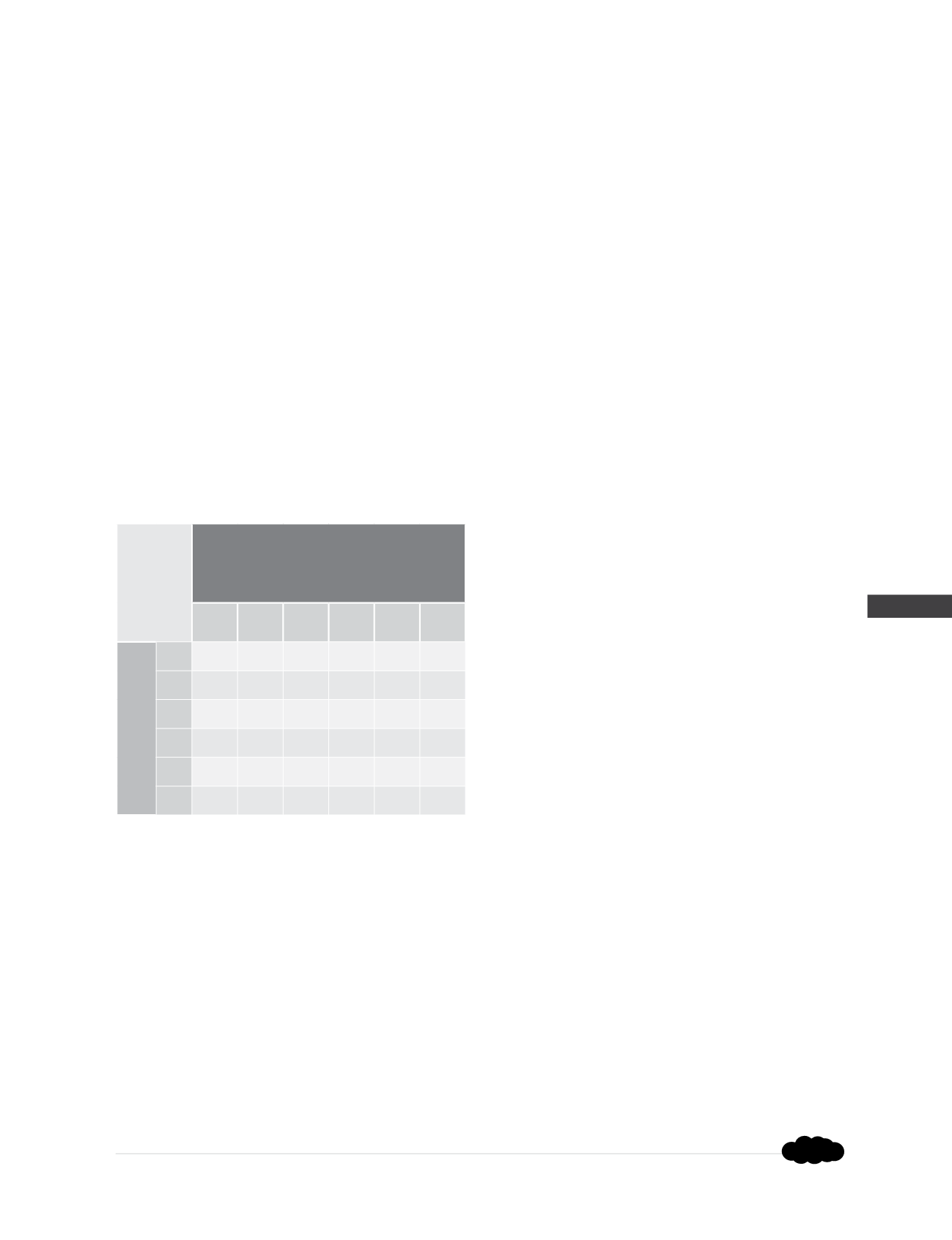

Wall Height (ft.)

4

5

6

7

8

9

Unbalanced fill Height (ft.)

4 6.0 6.0 6.0 6.0 6.0 6.0

5

6.0 6.0 6.0 5.5 5.0

6

6.0 5.5 5.0 4.5

7

5.0 4.5 4.0

8

4.0 3.5

9

3.0

1.

Maximum recommended spacing from corners is 2 feet.

2.

Spacing could be less than listed in the above chart based on the condition of the wall and severity of wall displacement.

3.

Because variations in building design and construction materials are common, PowerBrace

™

applications should be reviewed by a qualified

professional.

4.

Torque applied to the adjustment bolt at the top bracket should not exceed 45 ft-lb.

Rev. 8/03/16