© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 70

APPENDIX 2A

HELICAL PRODUCT RATINGS, PROPERTIES AND DETAILS

Chapter 2

Helical Foundation Systems

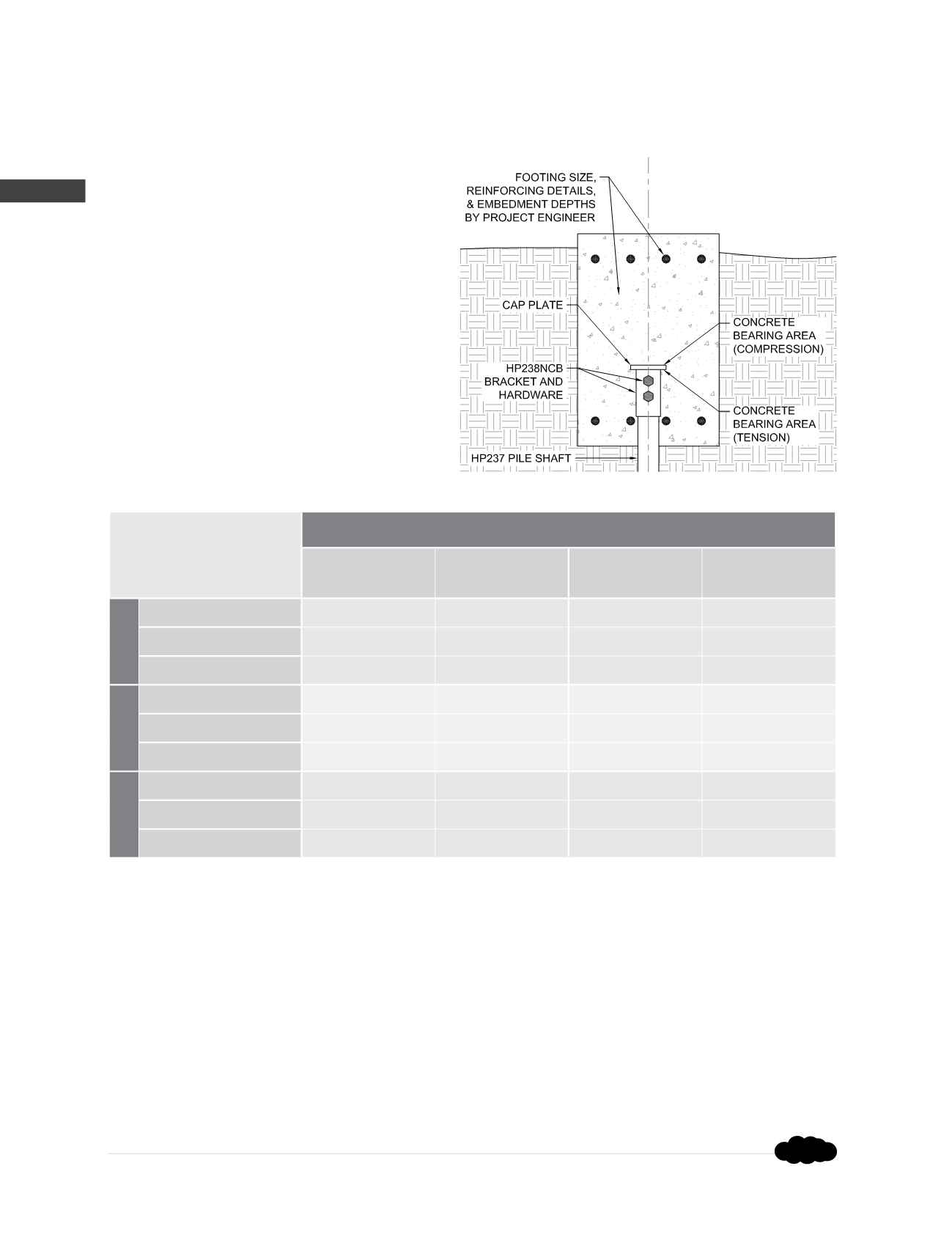

HP238NCB Bracket Specifications and Capacities

when used with the HP237 Helical Pile System

Bracket Sleeve Material:

Ø

2.750” x 0.156” wall

ASTM A513 Type 5 Grade 1026

Yield strength = 70 ksi (min)

Tensile strength = 80 ksi (min)

Cap Plate Material:

1

” x 4.00” square

ASTM A36

Bracket Hardware:

(2) -

Ø

5/8

” ASTM A325 bolts with nuts

Hot-dip galvanized per ASTM A153

Bracket Finish:

Available plain or hot-dip galvanized

(2)

Concrete Bearing Area

(6)

(Compression) = 16.0 in

2

Concrete Bearing Area

(6)

(Tension) = 10.1 in

2

Allowable Bracket Capacity

(4)

R

n

/Ω

Compression

(3)

(kips)

Concrete Bearing

(6)

(ksi)

Tension

(kips)

Concrete Bearing

(6)

(ksi)

2 Bolts

Plain

35.1

2.19

19.3

1.92

Plain Corroded

(1)

26.3

1.67

13.6

1.39

Galvanized Corroded

(1,2)

32.6

2.05

16.9

1.70

1 Bolt

Plain

35.1

2.19

9.7

0.96

Plain Corroded

(1)

26.3

1.67

6.8

0.70

Galvanized Corroded

(1,2)

32.6

2.05

8.5

0.85

0 Bolts

(5)

Plain

35.1

2.19

0

0

Plain Corroded

(1)

26.3

1.67

0

0

Galvanized Corroded

(1,2)

32.6

2.05

0

0

(1)

Corroded capacities include a 50-year scheduled sacrificial loss in thickness per ICC-ES AC358.

(2)

Hot-dip galvanized coating in accordance with ASTM A123.

(3)

Allowable compression capacities consider continuous lateral soil confinement in soils with SPT blow counts ≥ 4. Piles with exposed

unbraced lengths or piles placed in weaker or fluid soils should be evaluated on a case by case basis by the project engineer.

(4)

Listed capacities include limiting mechanical capacities of the shaft when the shaft and bracket are combined as a system. System

capacity should also not exceed the installed allowable torque-correlated soil capacity (See Shaft Specifications and Capacities).

(5)

Applications utilizing no bolts should either be tack welded or utilize some other mechanism to immobilize the bracket and maintain firm

contact between the cap plate and pile shaft throughout construction and concrete placement.

(6)

Concrete bearing values provided are the uniform bearing stresses required to achieve the full corresponding bracket capacity. Allowable

concrete bearing is a function of several project specific variables including depth of embedment, edge distance, and concrete compressive

strength (f’c). When allowable concrete bearing stresses are lower than these values, corresponding bracket capacities can be obtained

by multiplying the actual allowable concrete bearing stress by the respective bearing areas provided, but should not exceed the capacities

listed in this table. Other concrete design checks including shear, bending, and punching of the supported structure are also project

specific and shall be the responsibility of the project engineer.

Rev. 5/26/15