© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 210

APPENDIX 2H

DOCUMENTATION

Chapter 2

Helical Foundation Systems

ESR-3074

|

Most Widely Accepted and Trusted

Page 6 of 9

5.14

The minimum helical pile center-to-center spacing

must be three times the largest helical bearing plate

diameters. For piles with closer spacing, the pile

allowable load reductions due to pile group effects

must be included in the geotechnical report

described in Section 4.1.1 of this report, and must be

considered in the pile design by a registered design

professional. The spacing and load reductions, if

applicable, are subject to the approval of the code

official.

5.15

For piles supporting tension loads, the piles must be

installed such that the minimum depth from the

ground surface to the uppermost helix is 12D, where

D is the diameter of the largest helix. In cases where

the installation depth is less than 12D, the minimum

embedment depth must be determined by a

registered design professional based on site-specific

soil conditions, and the determination is subject to

the approval of the code official. For tension

applications where the helical pile is installed at an

embedment depth of less than 12D, the torque-

correlation soil capacity, P4, is outside of the scope

of this evaluation report.

5.16

Piles supporting compression loads must be

installed such that the minimum depth from the

bottom of the pile-supported footing to the

uppermost helix is no less than 5 feet (1524 mm).

For compression piles with a shallower helix depth,

the actual helix depth must be considered in the pile

design by a registered design professional. The

depth is subject to approval of the code official.

5.17

Evaluation of compliance with Section 1810.3.11.1 of

the 2012 and 2009 IBC (Section 1808.2.23.1.1 of the

2006 IBC) for buildings assigned to Seismic Design

Category (SDC) C, and with Section 1810.3.6 of the

2012 and 2009 IBC (Section 1808.2.7 of the 2006

IBC) for all buildings, is outside the scope of this

evaluation report. Such compliance must be

addressed by a registered design professional for

each site, and the work of the design professional is

subject to approval of the code official.

5.18

Requirements listed in the footnotes to Tables 1, 2,

3, and 5 must be satisfied.

5.19

Settlement of helical piles is beyond the scope of this

evaluation report, and must be determined by a

registered design professional as required in Section

1810.2.3 of the 2012 and 2009 IBC (Section

1808.2.12 of the 2006 IBC).

5.20

The FSI helical foundation systems are

manufactured at the following facilities: Distefano

Technology & Manufacturing Company, 3838 South

108

th

Street,

Omaha,

Nebraska;

Behlen

Manufacturing Company, 4025 East 23

rd

Street,

Columbus, Nebraska; and TSA Manufacturing,

14901 Chandler Road, Omaha, Nebraska.

Manufacturing is done under a quality control

program with inspections by ICC-ES.

6.0 EVIDENCE SUBMITTED

Data in accordance with the ICC-ES Acceptance Criteria

for Helical Pile Systems and Devices (AC358), dated

June 2013.

7.0 IDENTIFICATION

The FSI helical foundation system components described

in this report are identified by labels that include the report

holder’s name (Foundation Supportworks, Inc.); the name

and address of Distefano Technology & Manufacturing

Company, Behlen Manufacturing Company, or TSA

Manufacturing; the product name; the model number

(HP288); the part number; the evaluation report number

(ESR-3074).

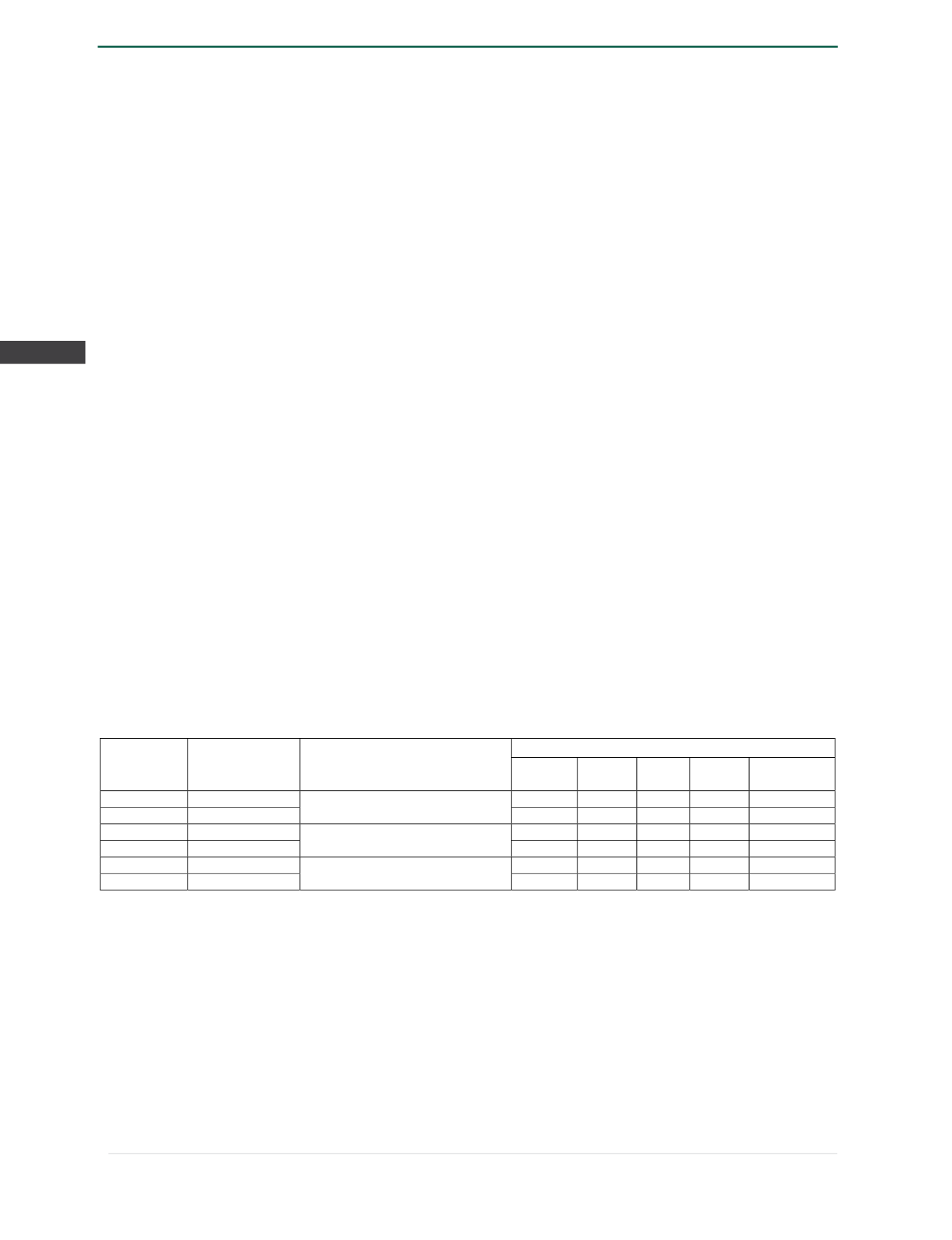

TABLE 1—HP288 (WITH RETROFIT BRACKETS) ASD COMPRESSION CAPACITIES

Bracket Part

No.

1

Sleeve Part No.

1

HP288 Bracket Description

Allowable Compression Capacity (kips)

Bracket

(P1)

2

Shaft

(P2)

3

Helix

(P3)

4

Soil

(P4)

5

Foundation

System

6

FS288B

FS288ES30

Standard Bracket w/30" Sleeve

24.9

60

55

35.5

24.9

FS288B-G

FS288ES30-G

27.9

60

55

35.5

27.9

FS288B

FS288ES48

Standard Bracket w/48" Sleeve

31.4

60

55

35.5

31.4

FS288B-G

FS288ES48-G

35.1

60

55

35.5

35.1

FS288BL

FS288ES30

Low Profile Bracket w/30" Sleeve

25.3

60

55

35.5

25.3

FS288BL-G

FS288ES30-G

28.2

60

55

35.5

28.2

For

SI:

I inch = 25.4 mm, 1 kip = 1000 lbf = 4.448 kN.

1

Part numbers with “G” suffix indicate hot-dip galvanized coating. Part numbers without a “G” suffix indicate plain steel.

2

Bracket capacity is based on full scale load tests per AC358 with an installed 5'-0" unbraced pile length per Section 1810.2.1 of the 2012 and

2009 IBC (Section 1808.2.9.2 of the 2006 IBC), having a maximum of one coupling.

3

Shaft capacity is applicable only to the foundation systems that are fully braced as described in Section 4.1.3.

4

Helix capacity is based on a single helix plate with outer diameter of 8, 10, 12 or 14 inches (203, 254, 305 or 356 mm).

5

Soil capacity is based on torque correlation per Section 4.1.5 of this report, with piles installed at the maximum torsion rating.

6

Foundation system allowable capacity is based on the lowest of P1, P2, P3 and P4 listed in this table. See Section 4.1.6 for additional

requirements.