© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 211

APPENDIX 2H

DOCUMENTATION

Chapter 2

Helical Foundation Systems

ESR-3074

|

Most Widely Accepted and Trusted

Page 7 of 9

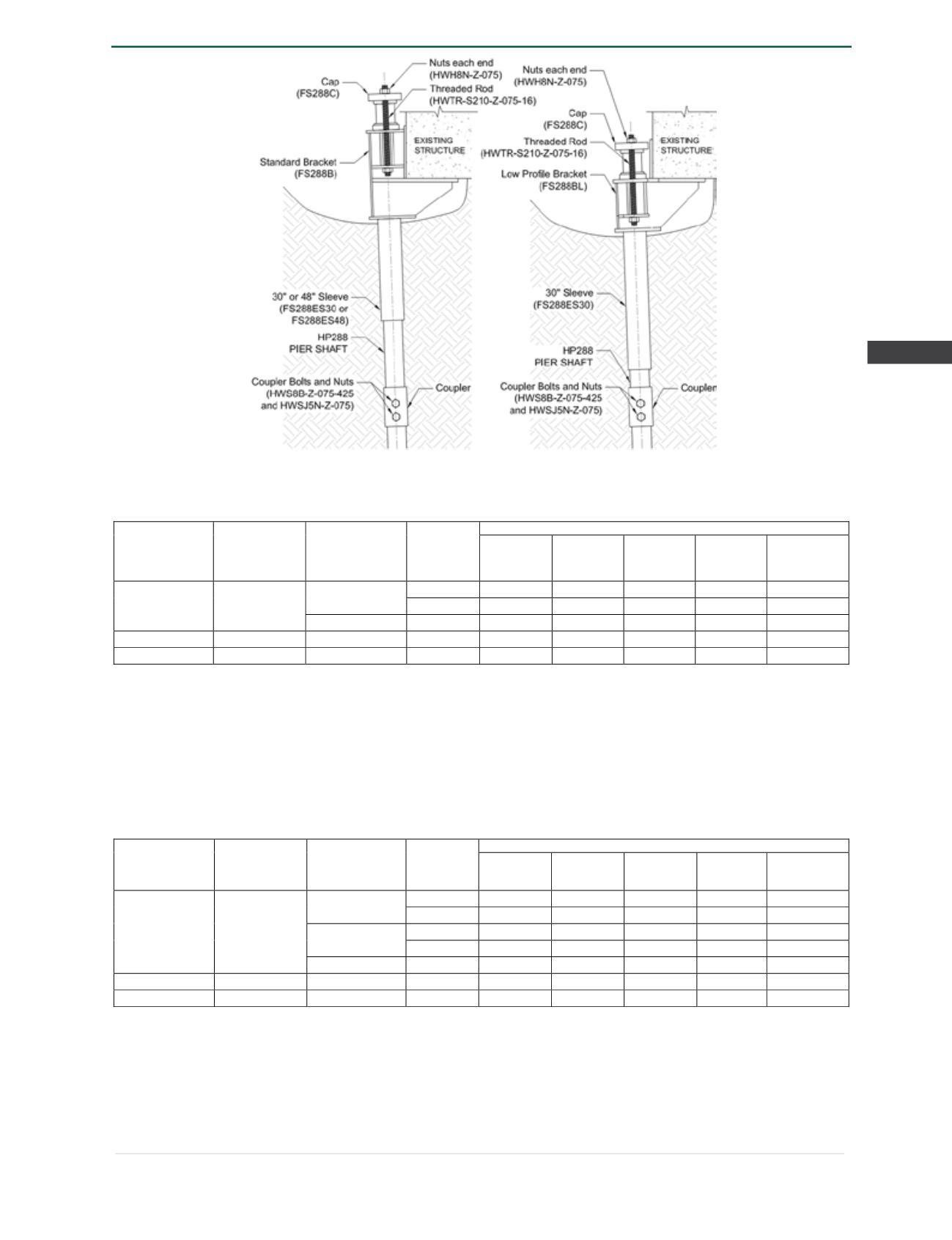

FIGURE 1—HP288 RETROFIT BRACKET AND SHAFT ASSEMBLIES

TABLE 2—HP288 (WITH NEW CONSTRUCTION BRACKETS) ASD COMPRESSION CAPACITIES

7

Bracket Part

No.

1

Bearing Plate

Dimensions

(in)

Minimum

Concrete

Compressive

Strength (psi)

Edge

Distance

"A" (in)

Allowable Compression Capacity (kips)

Bracket

(P1)

2

Shaft (P2)

3

Helix (P3)

4

Soil

(P4)

5

Foundation

System

6

HP288NCB or

HP288NCB-G

6 x 6 x 0.75

2500

3

33.1

60

55

35.5

33.1

≥ 4

44.1

60

55

35.5

35.5

3000

≥ 3

39.7

60

55

35.5

35.5

HP288NCB8

8 x 8 x 0.75

2500

≥ 4

43.1

60

55

35.5

35.5

HP288NCB8-G

8 x 8 x 0.75

2500

≥ 4

46.5

60

55

35.5

35.5

For

SI:

I inch = 25.4 mm, 1 kip = 1000 lbf = 4.448 kN.

1

Part numbers with “G” suffix indicate hot-dip galvanized coating. Part numbers without a “G” suffix indicate plain steel.

2

Bracket capacity is based on localized limit state of concrete bearing only. All other limit states related to the concrete foundation, such as punching

shear, have not been evaluated in this evaluation report.

3

Shaft capacity is applicable only to the foundation systems that are fully braced as described in Section 4.1.3.

4

Helix capacity is based on a single helix plate with outer diameter of 8, 10, 12 or 14 inches (203, 254, 305 or 356 mm).

5

Soil capacity is based on torque correlation per Section 4.1.5 of this report, with piles installed at the maximum torsion rating.

6

Foundation system allowable capacity is based on the lowest of P1, P2, P3 and P4 listed in this table. See Section 4.1.6 for additional requirements.

7

Reduction of plain concrete thickness described in Section 22.4.7 of ACI 318-11 for the 2012 IBC (Section 22.4.7 of ACI 318-08 for the 2009 IBC, and

22.4.8 of ACI 318-05 for the 2006 IBC) is assumed not applicable.

TABLE 3—HP288 (WITH NEW CONSTRUCTION BRACKETS) ASD TENSION CAPACITIES

6

Bracket Part

No.

1

Bearing Plate

Dimensions (in)

Minimum

Concrete

Compressive

Strength (psi)

Edge

Distance

"A" (in)

Allowable Tension Capacity (kips)

Bracket

(P1)

2,7

Shaft (P2)

Helix (P3)

3

Soil

(P4)

4

Foundation

System

5

HP288NCB

or

HP288NCB-G

6 x 6 x 0.75

2500

3

24.3

34.1

55

27.6

24.3

≥ 4

32.4

34.1

55

27.6

27.6

3000

≥ 3

29.1

34.1

55

27.6

27.6

3500

≥ 3

34.0

34.1

55

27.6

27.6

HP288NCB8

8 x 8 x 0.75

2500

≥ 4

34.1

34.1

55

27.6

27.6

HP288NCB8-G

8 x 8 x 0.75

2500

≥ 4

38.2

38.2

55

27.6

27.6

For

SI:

I inch = 25.4 mm, 1 kip = 1000 lbf = 4.448 kN, 1 psi = 6.895 kPa.

1

Part numbers with “G” suffix indicate hot-dip galvanized coating. Part numbers without a “G” suffix indicate plain steel.

2

Bracket capacity is based on localized limit state of concrete bearing only. All other limit states related to the concrete foundation, such as punching

shear, have not been evaluated in this evaluation report.

3

Helix capacity is based on a single helix plate with outer diameter of 8, 10, 12 or 14 inches (203, 254, 305 or 356 mm).

4

Soil capacity is based on torque correlation per Section 4.1.5 of this report, with piles installed at the maximum torsion rating.

5

Foundation system allowable capacity is based on the lowest of P1, P2, P3 and P4 listed in this table. See Section 4.1.6 for additional requirements.

6

Reduction of plain concrete thickness described in Section 22.4.7 of ACI 318-11 for the 2012 IBC (section 22.4.7 of ACI 318-08 for the 2009 IBC, and

22.4.8 of ACI 318-05 for the 2006 IBC) is assumed not applicable.

7

Bolts must be installed in accordance with Sections 3.2.2.2 and 4.2.4 of this report.