© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 259

APPENDIX 3A

BRACKET SPECIFICATIONS AND CAPACITIES

Chapter 3

Hydraulically-Driven Push Piers

Bracket:

Weldment manufactured from

1

”,

3/8

”,

and

1

” ASTM A36 plate.

Pier Tube:

Ø

2.875” x 0.165” wall x 36” long

Triple-coated in-line galvanized

ASTM A500 Grade C

Yield strength = 50 ksi (min)

Tensile strength = 55 ksi (min)

Pier Tube Coupler:

Ø

2.250” x 0.180” wall x 6” long

Pier Starter Tube:

Pier tube section with

Ø

3.375” friction

reduction collar pressed around leading end.

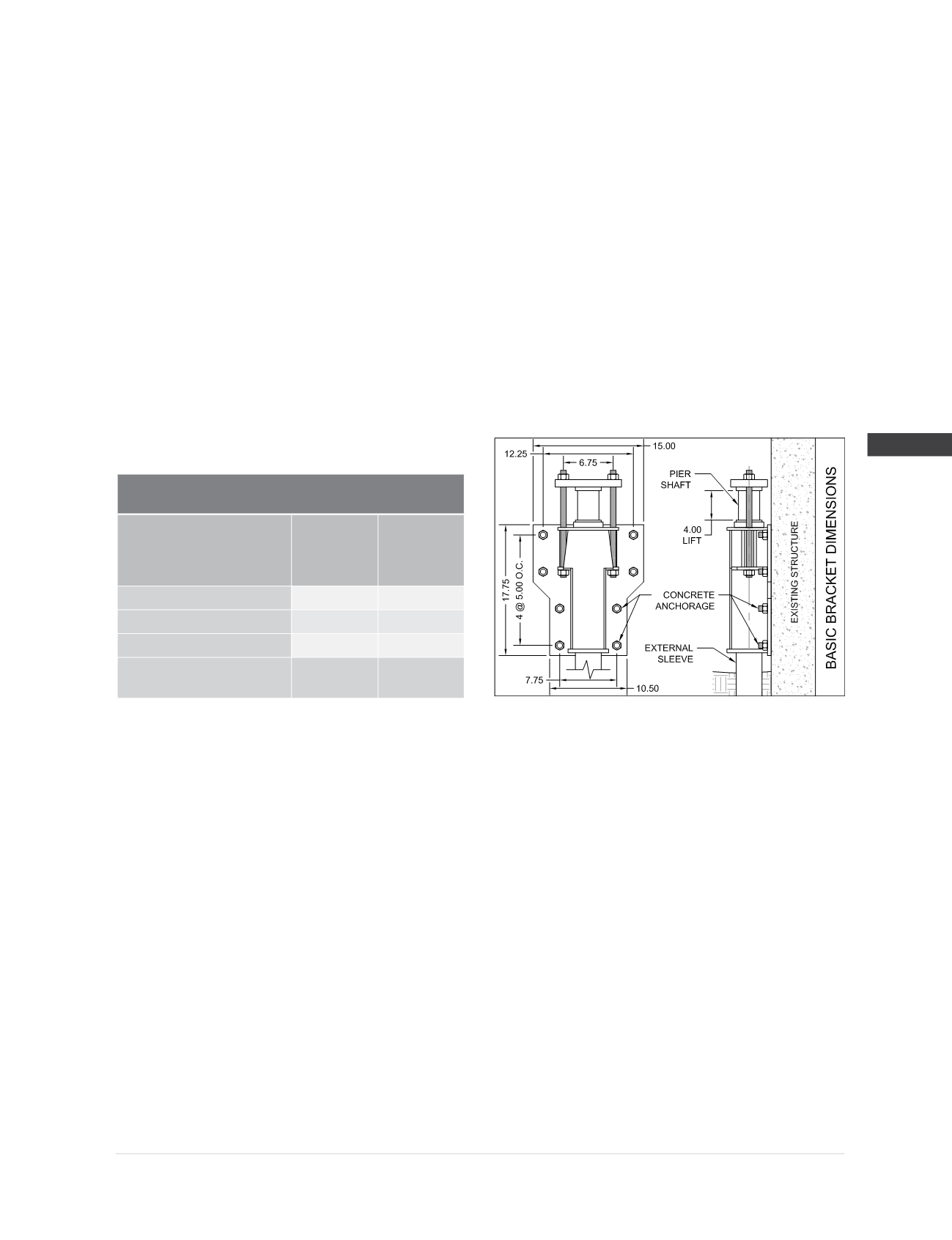

FS288BFM Bracket Specifications and Capacities

when used with the PP288 Push Pier System

Allowable Bracket Capacity

(4,5,6,9)

R

n

/Ω

with Wedge

Anchors

(7)

(kips)

with

Adhesive

Anchors

(8)

(kips)

Plain

22.0

31.0

Plain Corroded

(1)

17.0

24.0

Grout Filled Corroded

(1)

19.3

27.1

Maximum Drive Force

During Installation

(9)

44.2

60.0

(1)

Corroded capacities include a 50-year scheduled sacrificial loss in thickness per ICC-ES AC406. Grout filled piers consider a loss in thickness

at the outside diameter only.

(2)

Hot-dip galvanized coating in accordance with ASTM A123.

(3)

Optional hardware utilizes similar sized contour (coil) thread made from AISI 1045, tensile strength = 120 ksi. Slightly lower tensile strength

material does not govern the listed capacities.

(4)

Brackets shall be used for support of structures that are considered to be fixed from translation. Structures that are not fixed from translation

shall be braced in some manner prior to installing retrofit brackets systems.

(5)

Allowable compression capacities consider continuous lateral soil confinement in soils with SPT blow counts ≥ 4. Piers with exposed unbraced

lengths or piers placed in weaker or fluid soils should be evaluated on a case by case basis by the project engineer.

(6)

Bracket is strictly intended to be mounted to poured concrete structures. Bracket should never be mounted to CMU concrete block.

Anchorage assumes a minimum concrete compressive strength (f’c) of 2,500 psi and a minimum concrete thickness of 8”. Local concrete

bending and other local design checks should be evaluated on a case by case basis by the project engineer.

(7)

When the bracket is mounted with wedge anchors, the bracket shall be located with a minimum distance of 6” from the edge of the bracket to

any concrete edge. Wedge anchors require the use of a

Ø

3/4

” drill bit and a minimum embedment depth of 5”. Wedge anchors shall be installed

to a torque of 150 ft-lbs.

(8)

When the bracket is mounted with adhesive anchors, the bracket shall be located with a minimum distance of 9” from the edge of the bracket

to any concrete edge. Wedge anchors require the use of a

Ø

13/16

” drill bit and a minimum embedment depth of 5.50”. Adhesive anchors shall

be tightened to a snug tight condition after sufficient curing time.

(9)

Push Piers shall be installed with a driving force exceeding the required allowable service load by a sufficient factor of safety (FOS). FOS is

most commonly between 1.5 and 2.0, although a higher or lower FOS may be considered at the discretion of the pier designer or as dictated

by local code or project requirements.

External Sleeve:

Ø

3.500” x 0.216” wall x 30” or 48” long with

welded collar or trumpet flare at one end.

ASTM A500 Grade B or C

Yield strength = 50 ksi (min)

Tensile strength = 62 ksi (min)

Cap Plate:

1” x 5.00” x 9.00” ASTM A572 Grade 50

with confining ring welded to one side.

Bracket Hardware

(3)

:

(2) -

Ø

3/4

”x 16” long all-thread rod

Grade B7, tensile strength = 125 ksi (min)

Electrozinc plated per ASTM B633

Bracket Finish:

Available plain or hot-dip galvanized

(2)

Concrete Anchorage

(7)

(Option 1):

(8) -

Ø

3/4” x 7” Simpson Wedge-All

Mechanically galvanized per ASTM B695)

Concrete Anchorage

(8)

(Option 2):

Adhesive = Simpson AT

Quantity = approximately 1.25 oz per hole

(8) -

Ø

3/4

” x 7” long all-thread rod

Grade B7, tensile strength = 125 ksi (min)

Electrozinc plated per ASTM B633