© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 41

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.11 Design Examples

Three common methods for determining helical

pile capacity are presented in Section 2.7. The

individual bearing and cylindrical shear methods

are used during the design phase to calculate or

estimate the pile capacity. The torque correlation

method is generally used to confirm or verify pile

capacity during field installation. FSI promotes

the use of the individual bearing method for

design calculations, therefore, that method

will be used in the following examples. Helical

pile product ratings, properties and details are

provided in Appendix 2A.

HelixPro

®

Helical Foundation Design Software

for Professionals was created by Foundation

Supportworks to simplify the design process

for helical piles and tiebacks. HelixPro is a

web-based helical foundation design tool

available free of charge to design professionals.

For more information on HelixPro, please refer

to Appendix 2C.

2.11.1 Helical Piles

Example 1

Helical piles are proposed to support a new

structure. The proposed pile layout is shown

on the foundation plan along with a design

working load of 30 kips per pile with a factor of

safety (FOS) = 2. Preliminary product selection

suggests that the HP288 helical pile is the best

fit for this load condition with an ultimate torque

rated capacity of 71.1 kips. The allowable torque

rated capacity would then be 35.5 kips with a

FOS = 2. A geotechnical investigation was

completed for the project and the soil profile is

shown in

Figure 2.11.1.a

.

The helical piles will penetrate the upper fill and

medium stiff clay to bear within the deeper very

stiff clay. With the helix plates bearing entirely

within the very stiff clay soil below a depth of 15

feet, we can use the equation from Section 2.7.1

for purely cohesive soils with

Φ

= 0:

Q

u

= ∑A

h

(9c)

Solve for the required helix plate area:

A

h

= Q

u

/9c

Q

u

= Design Working Load (30,000 lb) x FOS

(2) = 60,000 lb

c

= 3,000 lb/ft

2

A

h

= 60,000 / (9)(3,000)

A

h

= 2.22 ft

2

Helix plate areas for the various shaft sizes can

be found in Appendix 2A. For the HP288 shaft

(2.875-inch O.D.), a total helix plate area of

2.22 ft

2

can be most efficiently achieved with a

10/12/14 triple-helix plate configuration.

A

10”

= 0.50 ft

2

A

12”

= 0.74 ft

2

A

14”

= 1.02 ft

2

∑A

h

= 2.26 ft

2

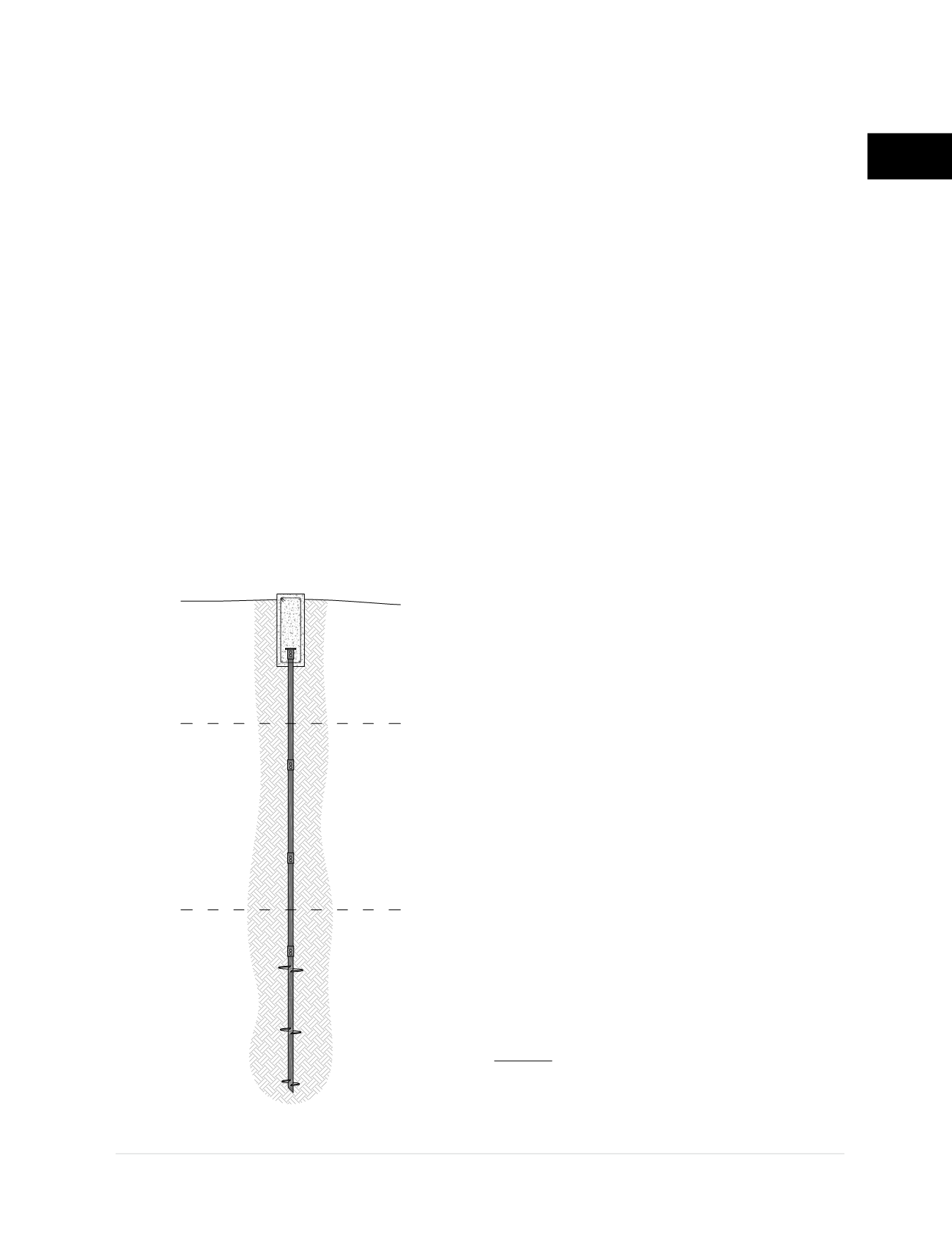

Figure 2.11.1.a

Example 1. Helical Pile Capacity

Loose Sand Fill

(Highly Variable)

6’

Medium Stiff Clay

c= 750 lb/ft

2

Φ = 0

γ

moist

= 115 Ib/ft

3

15’

Very Stiff Clay

c= 3,000 lb/ft

2

Φ = 0

γ

moist

= 120 Ib/ft

3