© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 42

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

Solve for the ultimate and allowable pile

capacities:

Q

u

= (2.26)(9)(3,000) = 61,000 lb = 61 kips

The allowable pile capacity,

Q

a

= Q

u

/ FOS

Q

a

= 61,000 / 2 = 30,500 lb = 30.5 kips…OK

Determine the required final installation

torque in accordance with the equations and

procedures of Section 2.7.3:

Q

u

= K

t

T

The equation can be rewritten to solve for torque:

T = Q

u

/ K

t

Without site-specific load testing and

determination of K

t

, we use the default value

from ICC-ES AC358 for a 2.875-inch O.D.

shaft, K

t

= 9 ft

-1

:

T

= 60,000 / 9 = 6,667 ft-lb

Install the helical piles to a final installation

torque of at least 6,700 ft-lb.

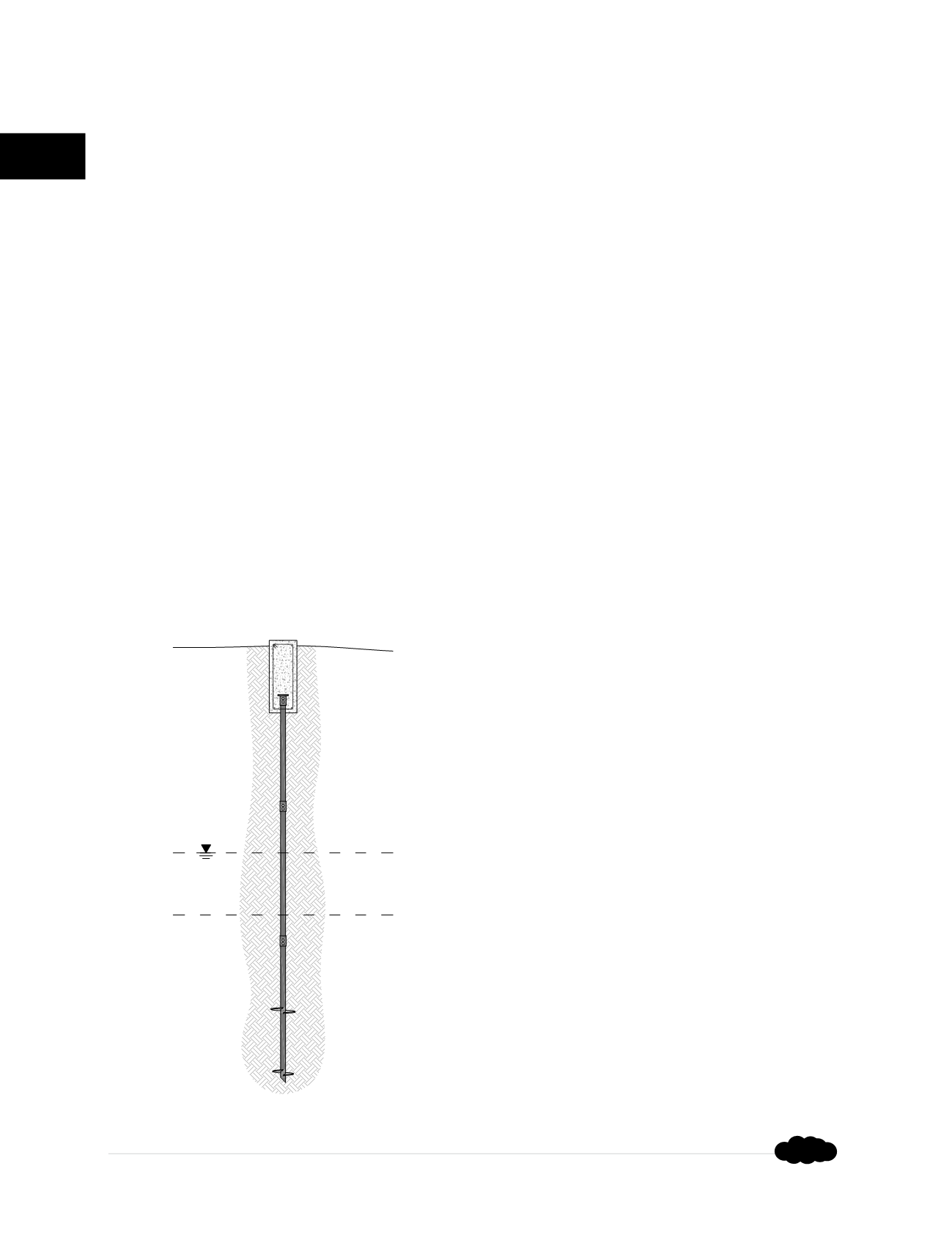

Example 2

Grain conveyor towers will be constructed at

an ethanol facility. The towers will be designed

with four support legs, each leg designed for

working loads of 40 kips in compression and 15

kips in tension/uplift. A FOS = 2 is required for

both the compression and uplift pile capacities.

A geotechnical exploration was completed

for the project and the soil profile is shown in

Figure 2.11.1.b

. Groundwater was encountered

at a depth of 10 feet below the surface.

Preliminary product selection suggests that the

HP350 helical pile is best suited to support the

proposed loads. The HP350 has an ultimate

torque rated capacity of 122.5 kips and an

allowable capacity of 60 kips (FOS = 2.04; see

footnote 7 on page 61). Allowable mechanical

compression and tension capacities are well

above the service loads to be resisted. The

helical piles will be embedded into the dense

sand as shown in

Figure 2.11.1.b

.

For purely granular (frictional) soils with c = 0,

the ultimate pile capacity can be determined

from equation:

Q

u

= ∑A

h

(q’N

q

)

Solve for the required helix plate area:

A

h

= Q

u

/q’N

q

The helix plates should be embedded several

plate diameters into the dense sand to provide

uplift resistance. This depth depends upon the

pile load. We can fine tune the embedment

depth at a later point, but for an uplift load of

15 kips, we’ll consider a minimum helix plate

embedment of three diameters. A pile with an

ultimate capacity of 80 kips often has three helix

plates on the lead section. A 10/12/14 lead has

a distance of 5.5 feet between the uppermost

and bottommost plates. With these parameters

in mind, we’ll choose a trial depth of:

13 feet + 3.5 feet (depth of 14-inch plate into

dense sand) + 2.75 feet (half the distance

between bearing plates) = 19.5 feet.

Figure 2.11.1.b

Example 2. Helical Pile Capacity

Groundwater

Table

10’

Loose Sand

c= 0

Φ = 30°

γ

moist

= 110 Ib/ft

3

γ

sat

= 115 Ib/ft

3

13’

Dense Sand

c= 0

Φ = 38°

γ

moist

= 120 Ib/ft

3

γ

sat

= 130 Ib/ft

3

Rev. 10/14/16