© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 224

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

3.3. Push Pier

System Components

FSI push pier system components are

manufactured to high quality control standards

using ASTM grade steel and certified welding

processes. The product line includes Models

PP237, PP288, PP350andPP400, corresponding

to shaft sizes of 2.375-inch, 2.875-inch, 3.50-

inch and 4.00-inch O.D, respectively. Various

exterior sleeve and bracket options are available.

Push pier system capacities and specifications

are provided Appendix 3A. The FSI push pier

system components include the following:

3.3.1 Bracket Assemblies

Bracket assemblies may include an under-footing

bracket, flush-mount bracket or a slab bracket.

Under-footing brackets are typically placed against

and below the footing and have vertical and

horizontal bearing plates. Under-footing brackets

have been designed to allow piers to be driven

vertically or at 2 degrees from vertical orientation.

Two-degree brackets are standard for the PP237

and PP288 systems as it allows the brackets to

be seated beneath foundation walls as much as

practical and provides separation for the drive stand

to miss common brick overhangs and window and

door trim on residential structures. Independent

testing of the PP288 push pier systemwith both the

FS288B (2-degree) and FS288BV (vertical) brackets

has shown less than 1 percent difference in the

capacities. Flush-mount brackets have a vertical

bearing plate anchored to the vertical concrete face

of the footing, grade beam or foundation wall. Slab

pier brackets are plate assemblies constructed

under the concrete floor slab via holes cored in the

slab. Pier sections driven through flush-mount and

slab pier brackets are in a vertical orientation only.

The FSI bracket assemblies generally include the

bracket, pier cap, external sleeve and associated

hardware. However, the Model PP400 push pier

system and the Model PP288 slab pier system are

designed without external sleeves. See Appendix

3A for mechanical ratings of the various push pier

systems and bracket assemblies.

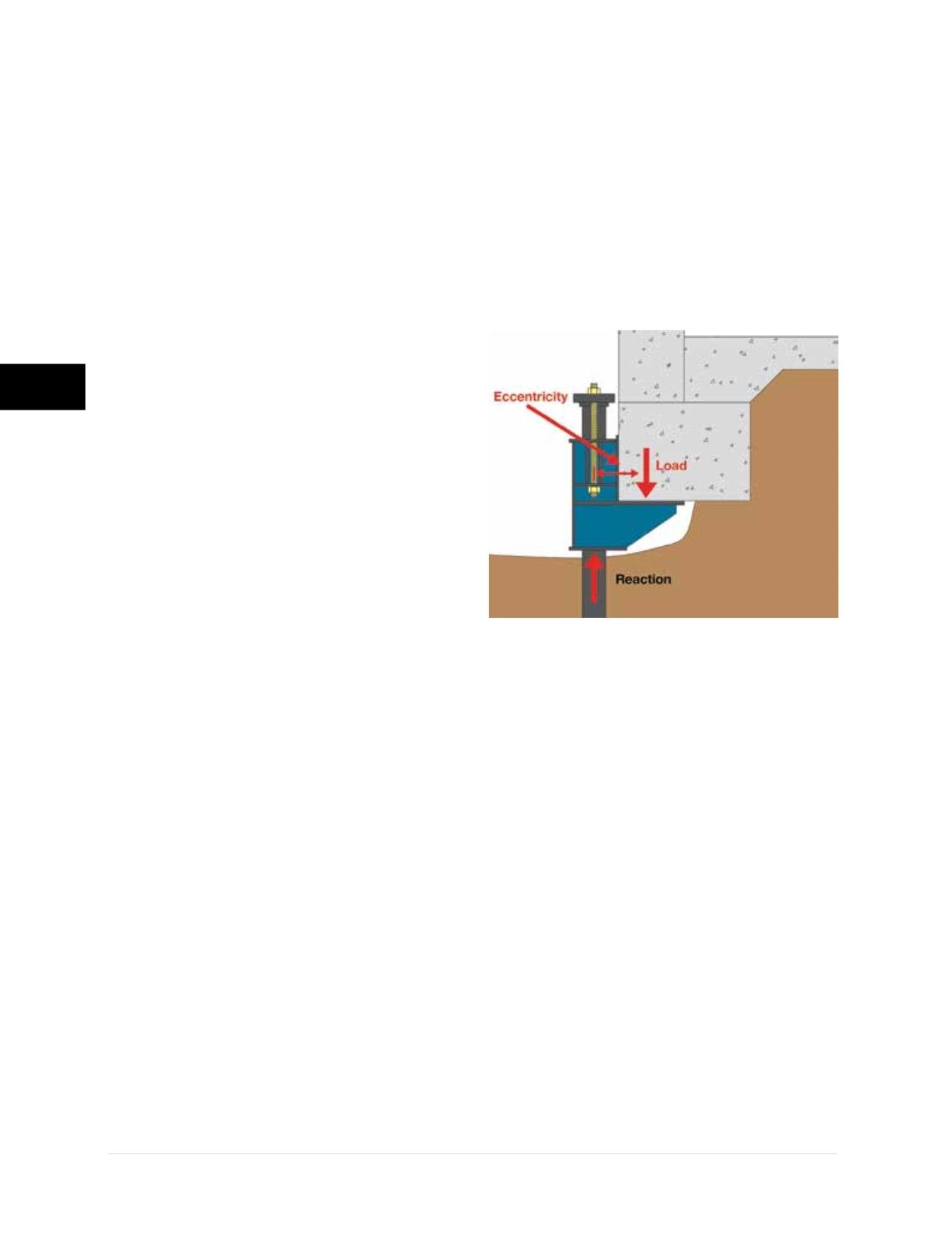

3.3.1.1 Eccentric Loading

Pier tubes of push pier systems utilizing under-

footing and flush-mount brackets are not

located directly under the structure’s footing.

Therefore, these systems are eccentrically

loaded and in turn need to resist the bending

forces generated by this loading condition

(Figure 3.3.1.1.a)

. The eccentricity generated by

under-footing and flush-mount bracket systems

is in reality shared by the pier and the structure.

In general, the more rigid the pier system and

its connection to the foundation, the more the

system acts as an extension of that foundation

and the more eccentricity must be absorbed by

the structure. This bending or twisting imparted

to the structure can be resisted by the internal

strength of the foundations and connections

to the superstructure, by passive resistance of

the soil along the opposite face of the footing

and/or foundation wall, by bracing with internal

structural elements such as floor slabs and

shear walls, and by support generated at

building corners. When the eccentricity cannot

be resisted by such conditions, the piers can

be staggered or paired on opposing sides of

the foundation. Multiple piers are often needed

at column locations simply to balance the load

and prevent tipping of the footing. Evaluation of

the eccentric loading condition on the structure

should be completed by a qualified design

professional on a case by case basis.

Figure 3.3.1.1.a

Eccentric loading

condition for under-footing bracket