© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 226

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

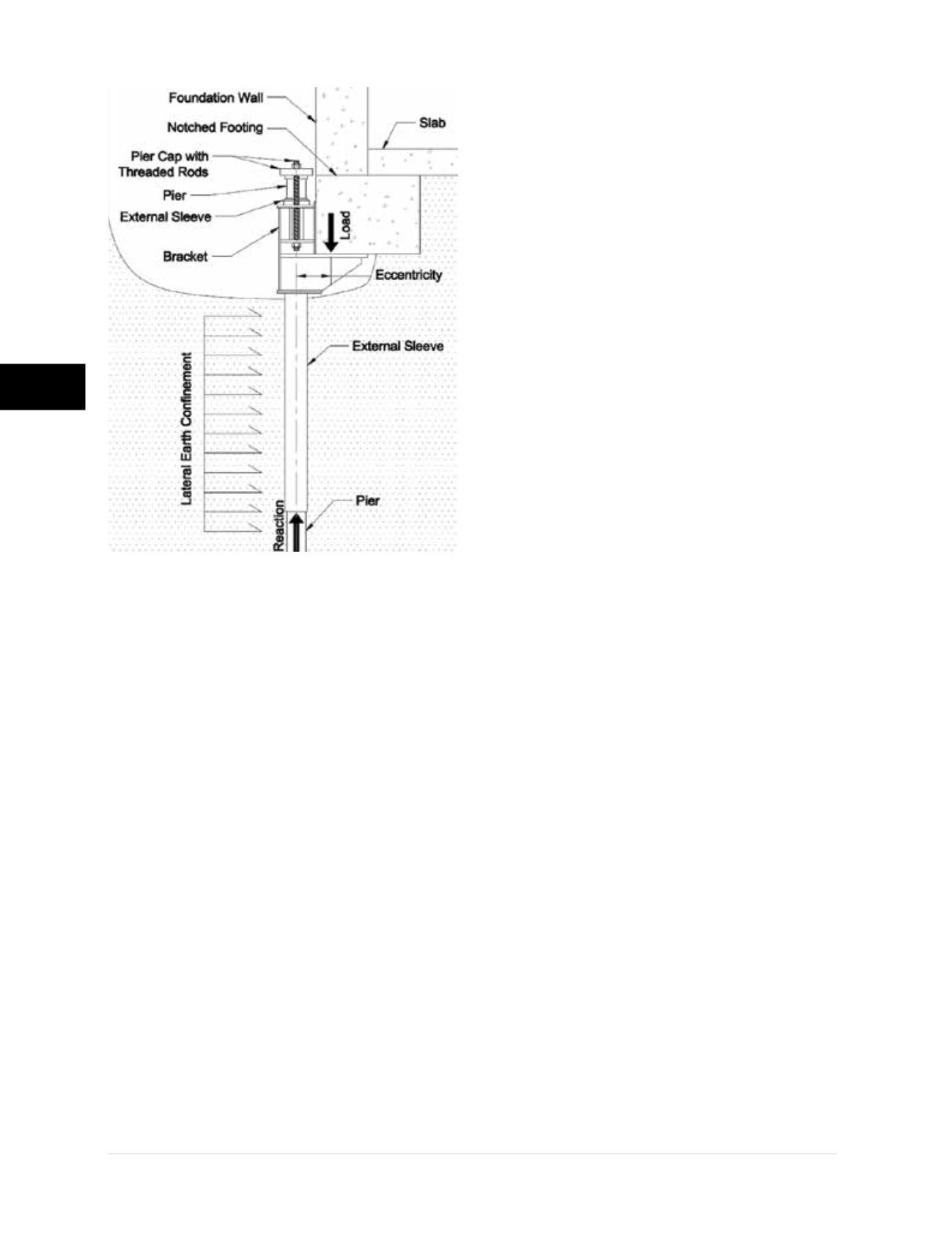

depth or length of sleeve and pier over which

the bending force dissipates is a function of the

soil stiffness. The depth is greater in soft clay

and loose sand, and less in stiff clay and dense

sand. Finite element analysis software was used

to analyze how the external sleeve and the pier

interact with soils of various properties. Bracket

rotation is resisted not only by the rigidity of the

pier system, but also by the passive pressure

of the soil surrounding the external sleeve and

pier. Therefore, the capacity and performance

of the pier system is in part governed by the

stiffness of the confining soils.

Benefits/advantages of an external sleeve include:

• Sleeved system separates the bending forces

from axial compression forces.

• Sleeve resists most of the bending forces and

behaves purely as a beam.

• Pier tube is protected from the bending forces

preserving its axial capacity so it can behave

more like a column.

• Sleeve is easy to install. It’s driven at the same

time as the starter tube.

• No cumbersome reinforcement to install after

driving pier tubes.

• The extra steel is where it needs to be. Much

more efficient than using thicker pier tube

sections for the entire length. It’s a local

solution to a local issue.

• Sleeve is in place during the system’s

maximum load (driving tubes).

• Relieves friction between pier bracket and pier

tube. Drive and lift pressures more accurately

reflect the load on the pier system.

3.3.2 Starter Tube

The starter tube is the first pier section pushed into

the ground and is installed at the same time as the

external sleeve, where applicable. Under-footing

and flush-mount bracket systems utilize a friction

reduction collar at the bearing end of the starter

tube. The friction reduction collar will be discussed

in more detail in the following section. Models

PP237 and PP288 starter tubes come in standard

lengths of 32 and 50 inches. The 32-inch starter

tubes are used in limited access and low headroom

applications, such as within a crawl space, along

with a modified (shorter) drive stand, shorter drive

cylinder, a 30-inch long external sleeve and 18-inch

long pier tubes. The PP350 system uses a 50-inch

long starter tube only, to coincide with the standard

48-inch long external sleeve. The PP350 is a higher

capacity system and generally not ideal for crawl

space applications. The PP400 system uses a

starter tube length consistent with the standard

36-inch pier tube length. The PP400 system is

unique in the FSI push pier product line in that the

under-footing bracket assembly does not include

the 48-inch long external sleeve and, therefore, no

special design or installation considerations have

to be made for starter tube length. The PP288 slab

pier system does not utilize a starter tube with a

friction reduction collar. The first section advanced

consists of a field-modified standard pier section

(see Section 3.12).

Figure 3.3.1.2.a

External sleeve and pier bear

against confining soil when system is under load