© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 330

APPENDIX 4D

SMARTJACK® SYSTEMS

Chapter 4

Miscellaneous Structural Support Products

SJ350TI (Threaded Insert):

Ø

3.500” x 1.00” thick machined and tapped insert,

ASTM A108 Grade 1018.

Yield strength = 56 ksi (min.), tensile strength = 90 ksi (min.).

Allowable compression for system heights up to 9 feet = (will

not govern)

SJ350T36, SJ350T60,

SJ350T84, SJ350T108, SJXT350T108 (Tube):

Ø

3.500” x 0.165” wall x 36”, 60”, 84”, or 108” long,

field cut to length, ASTM A500 Grade C

triple-coated in-line galvanized.

Yield strength = 50 ksi (min.), tensile strength = 55 ksi (min.).

Allowable compression for system heights up to 9 feet = 20.0 k

SJAFTG (Cast Aluminum Base):

0

.85” x 12.00” square AISI/AA 356.0-T6

cast aluminum. Yield strength = 20.0 ksi (min),

tensile strength = 30.0 ksi (min.).

Allowable compression = 8.0 k

SJ350BP (Bottom Plate):

1

” x 3.50” square ASTM A36 plate and

Ø

3.125” x 0.187”

wall x 0.75” long ASTM A53 Grade B confining ring.

Allowable compression (when used against concrete with

minimum f’c = 2,500 psi) =10.7 k

Precast Concrete Footing

Typical base dimensions approx. 12” x 12”. Exact

dimensions and capacities vary with manufacturer. Item

purchased at local building supply center.

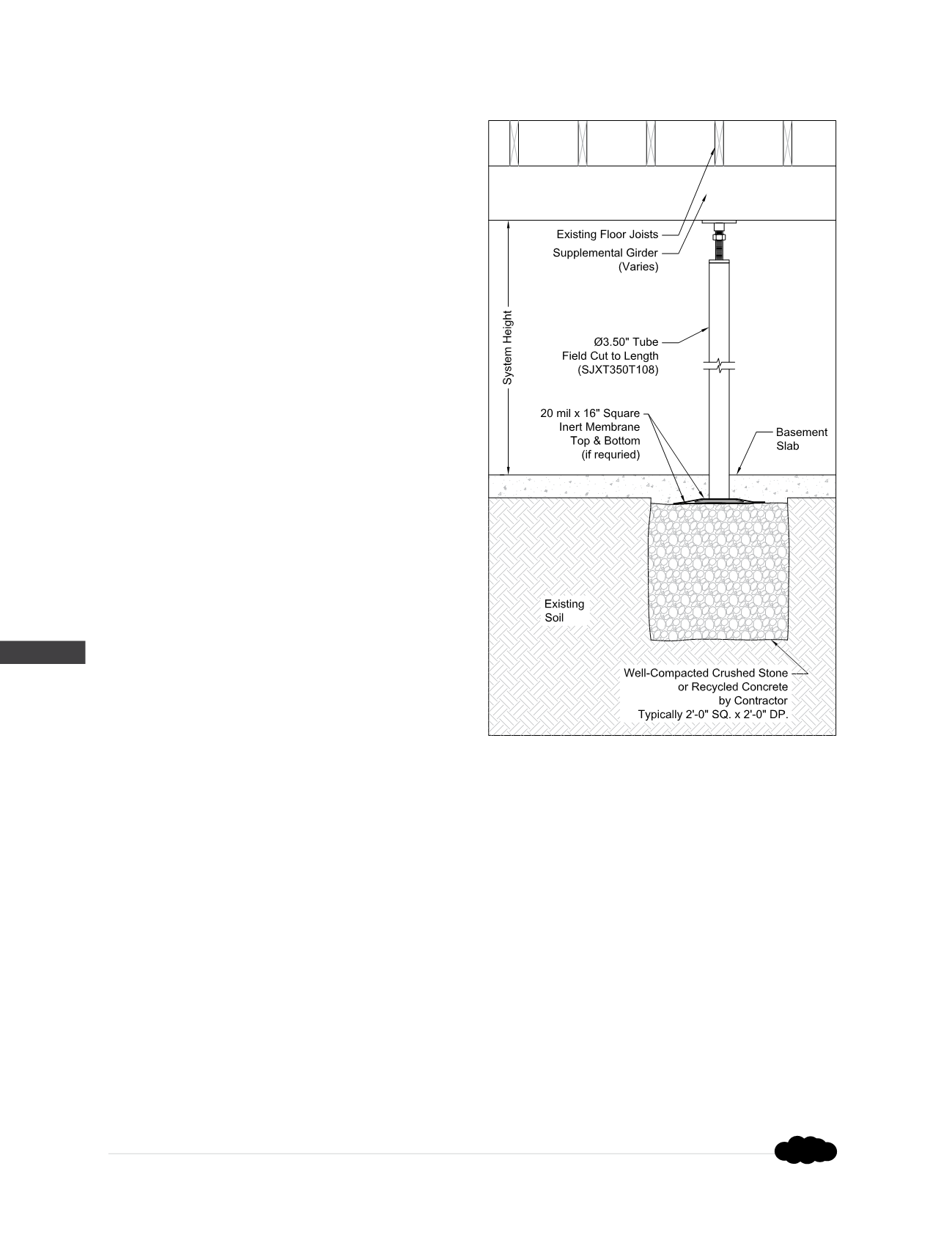

Typical Basement Detail

Note:

Threaded insert is welded to tube

for basement applications (SJXT350T108).

Remaining details are consistent with those

shown for crawlspace applications.

Allowable Capacity

The allowable system compression capacity of the assembled SmartJack

®

system is limited to the

least value of the component capacities used in the system assembly. The component capacities are

listed in the technical specifications section.

The allowable load applied to the SmartJack

®

system may be limited by the bearing capacity of the

existing soil. The well-compacted crushed stone or recycled concrete base is a proven method to

increase support for the higher bearing pressure condition immediately below the cast aluminum base

or the concrete footing, and then to absorb and distribute lower pressures to the existing soils. Should

settlement of the SmartJack

®

system occur, adjustments are made easily by extending the all-thread rod.

Rev. 1/15/16