© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 331

APPENDIX 4D

SMARTJACK® SYSTEMS

Chapter 4

Miscellaneous Structural Support Products

The SmartJack

®

is designed to support axial compression loads only. The SmartJack

®

should

not be used in applications where the system is intended to resist lateral loads.

Corrosion Protection

The tube steel used for the SmartJack

®

is manufactured with a triple-layer, in-line galvanized coating.

This coating process consists of: (1) a uniform hot-dip zinc galvanizing layer; (2) an intermediate

conversion coating to inhibit the formation of white rust and enhance corrosion resistance; and (3) a

clear organic top coating to further enhance appearance and durability. The inside of the pier tube

also has a zinc-rich coating.

The cast aluminum base is far less susceptible to corrosion than the steel components that

surround it. There are, however, chlorides in some concrete that can be reactive with aluminum. It is

recommended that a 20 mil x 16” square inert membrane be placed under or around the aluminum

base to seperate it from recycled or poured concrete. Crushed limestone or other crushed stone

alternatives do not have similar considerations.

The remaining steel components of the SmartJack

®

system come standard as electrozinc plated per

ASTM B633.

Design Example

Step 1

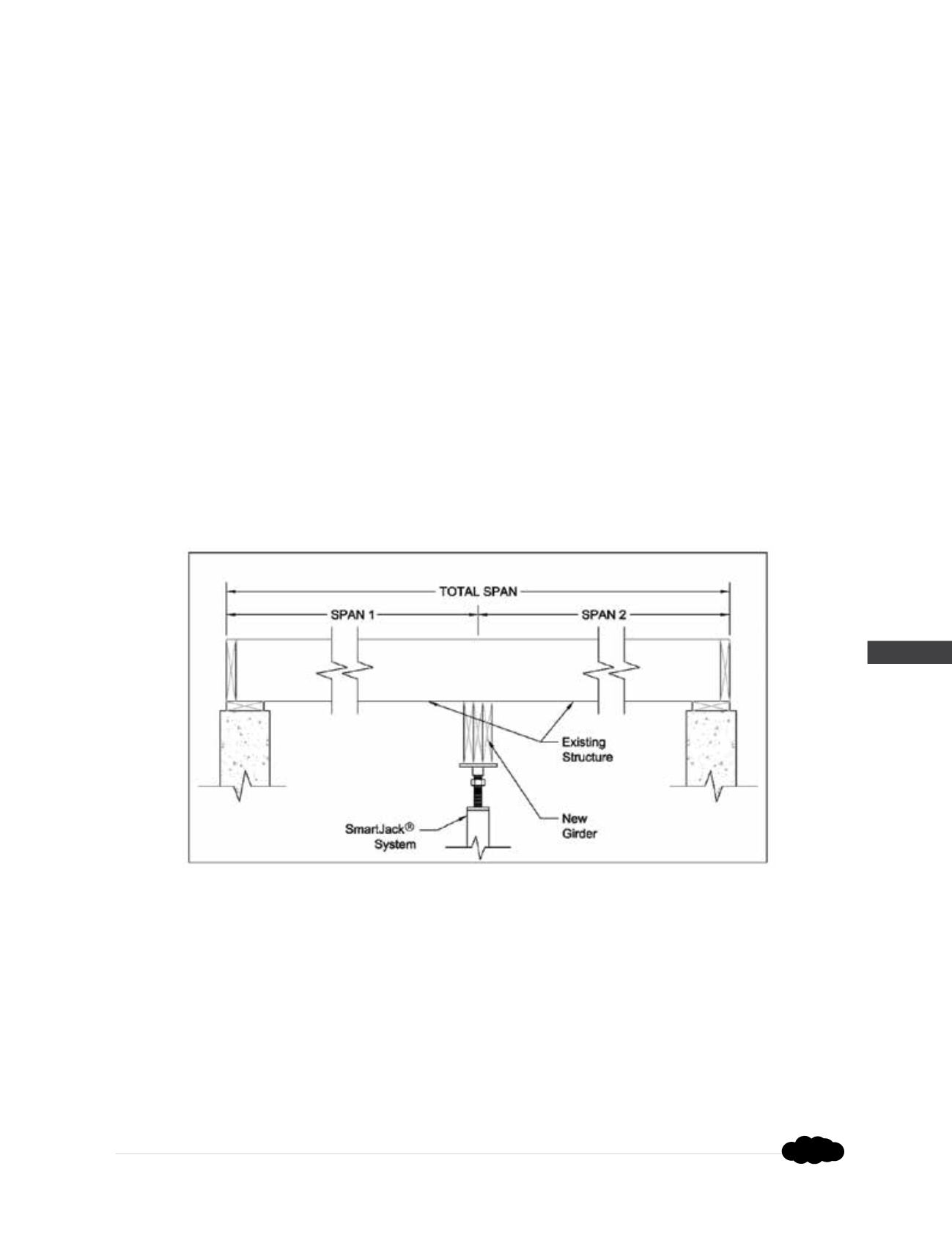

- Determine the load which will be supported by the girder in pounds per linear foot:

Girder Load (plf) = (Span 1 (ft) + Span 2 (ft)) x Floor Load (psf) ÷ 2

Note 1:

Typical residential wood-framed construction may have an approximate floor load (dead

load + live load) = 55 psf

Note 2:

This equation assumes a floor system which does not support any load bearing walls

or columns.

Step 2

- Determine the load on the SmartJacks

®

by multiplying the calculated Girder Load (plf) by the

spacing of the SmartJacks:

SmartJack Load (lbs) = Girder Load (plf) x SmartJack

®

Spacing (ft)

Rev. 9/23/15