© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 336

Chapter 5

PolyLEVEL

®

Polyurethane Foam and Resin

CHAPTER 5

POLYLEVEL

®

POLYURETHANE FOAM AND RESIN

5.3 Benefits

There are many benefits and advantages to

using PolyLEVEL foams over other products,

repair options, and stabilization methods.

•

Lightweight

– PolyLEVEL polyurethane foams

weigh only 4 to 7 pounds per cubic foot (pcf)

when installed and confined beneath slabs

and pavements. Mudjacking material and

compacted fill soil can weigh 100 to 140

pcf. Very little load is therefore added to the

underlying, supporting soils.

•

High Capacity

– Lifting action is the result of

the expansion of the polymer, not the pressure

at which PolyLEVEL is injected beneath the

slab. This generally allows for lifting of higher

loads than mudjacking. Mudjacking relies

on the hydraulic pressure being contained

beneath the slab. When mudjacking slurry

“blows out”, additional lift is not possible.

•

Accurate Lift

– Installer technique and

product knowledge allows for precise lifting

(Figures 5.3.a1 and 5.3.a2)

. Each product has

a calculated reaction time.

•

Waterproof

– PolyLEVEL foam will not soften,

“dissolve” in water, or wash out. Material can

be used to under-seal slabs as well as stop a

variety of infrastructure leaks. PolyLEVEL slab

support products will not absorb water and are

therefore unaffected by freeze-thaw cycles.

•

Non-Invasive

– PolyLEVEL installation

equipment allows placement in tight and

limited access areas. There is less mess than

mudjacking and smaller

5/8

-inch holes required

for installation. Mudjacking typically requires 2

to 3-inch holes. PolyLEVEL installs quickly and

most small projects are completed in one day.

•

Quick Cure Time

– PolyLEVEL foam cures

quickly to allow even heavy traffic just 30

minutes after installation.

•

Environmentally Friendly

– The two parts (A

and R sides) react fully with each other and

create an inert product safe for the environment.

Use of PolyLEVEL to stabilize and re-level

slabs extends pavement life so less material is

removed and hauled off to landfills.

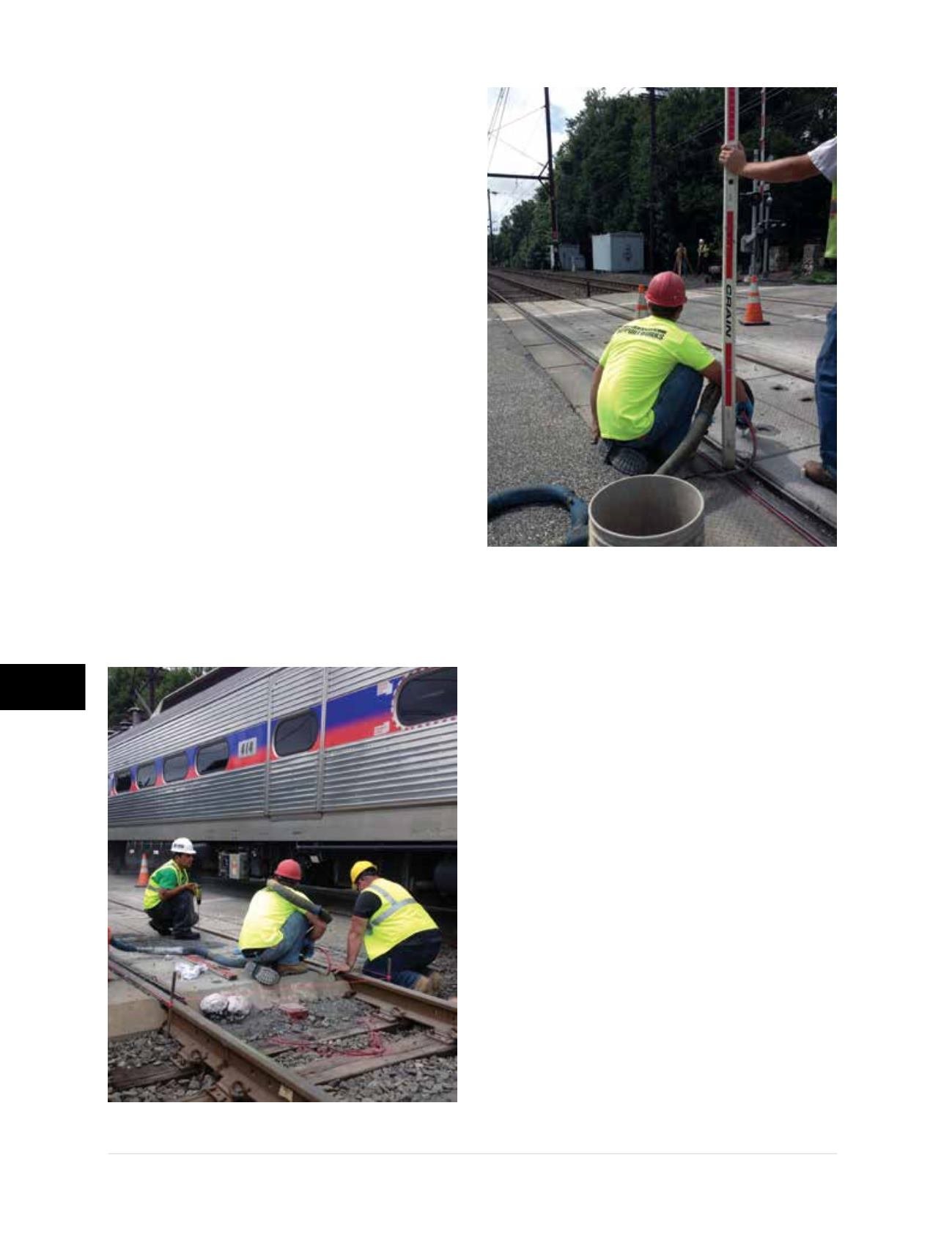

Figure 5.3.a1

Commuter train track

settled up to 2 inches at intersection

Figure 5.3.a2

Lifting precast concrete slabs and embedded

rails while monitoring with survey equipment