© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 34

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

• There is no need to embed structural elements

below the proposed ground surface elevation

on the low side of the soil nail wall. Soldier

pile and sheet-pile walls require minimum

embedment depths for wall stability.

• Soil nail wall construction is typically quicker

than other earth retention methods.

• Soil nail walls can be constructed in remote

areas with smaller equipment.

• Soil nail walls have performed well during

seismic loading events due to the overall

system flexibility.

A helical soil nail typically consists of square shaft

lead and extension sections with small diameter

(6 to 8 inches) helix plates spaced evenly

along the entire shaft length

(Figures 2.9.a1

and

2.9.a2)

. The helical soil nail is installed by

application of torque, similar to the installation of

a helical tieback. The helical soil nail is a passive

bearing element, which relies on movement

of the soil mass and active earth pressures to

mobilize the soil shear strength along the nail. In

contrast, a tieback is pre-tensioned to mobilize

the soil shear strength around the helix plates.

Excavation, soil nail installation and application

of wall facing is completed in steps from the top

of the wall downward.

2.9.1 Construction

Methodology

Soil nail walls are constructed from the top

down where the excavation proceeds as shown

in

Figure 2.9.1.a

. The construction sequence for

a typical helical soil nail wall includes:

• Initial excavation about 3 to 5 feet deep

depending upon design parameters and

soil conditions

• Installation of the first row of helical soil nails

to the required inclination angle, torque and

embedment length

• Placement of drainage medium (if required)

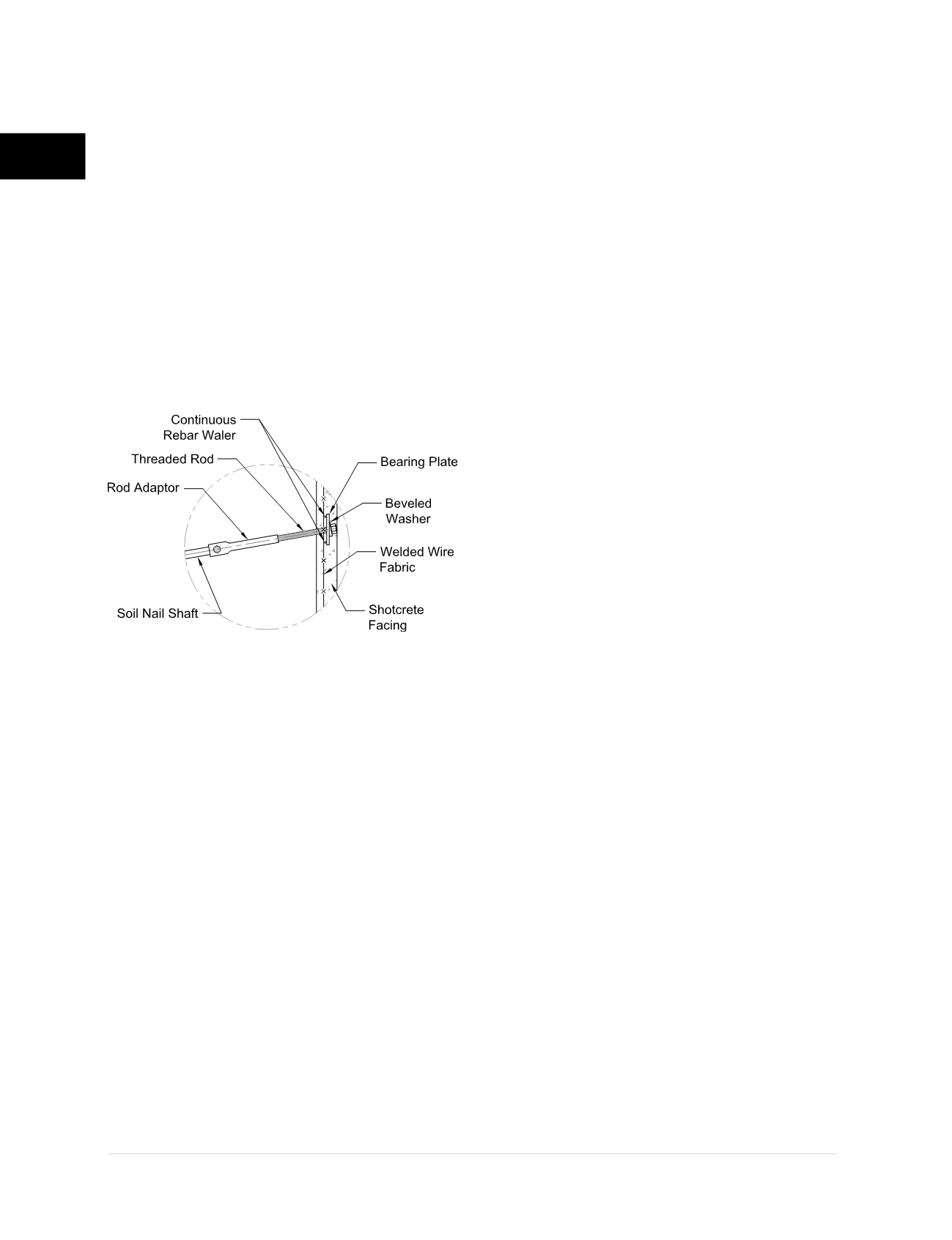

• Placement of wall reinforcement and bearing

plates

• Placement of shotcrete to the required design

wall thickness

• After shotcrete has cured, repeat sequence

for successive rows of soil nails. Continue

process to the final design depth (wall height).

Figure 2.9.a2

Nail head to wall detail