© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 32

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

walls, for example, are generally designed with

significant reinforcing steel on the backfilled

side of the wall where tension and bending

are greatest. Reinforcing steel within the

compression side of the wall is generally the

minimum required by code. Tieback installation

induces a negative bending in the cantilevered

wall for which the wall was not originally

designed. Walls to be stabilized with tiebacks, or

walls that will be designed with tieback support,

should be reviewed by a design professional.

The assumed failure plane behind an earth

retaining wall is dependent upon soil conditions

and wall type. As a general rule of thumb, a failure

plane can be projected from the bottom back face

of the wall upward at an angle of 45-

Φ

/2 (degrees)

from vertical for both active and at-rest conditions.

For retaining walls and basement walls, this failure

plane is usually assumed to begin at the bottom

of wall. For sheet pile walls, the failure plane is

usually assumed to begin at the mud line.

Failure modes for restrained walls should be

evaluated for internal stability, external stability,

bearing capacity and global stability. It is the

responsibility of the design professional of record

to perform these evaluations. Typical factors of

safety for helical tiebacks used in conjunction

with earth retention systems are generally on

the order of 1.3 to 1.5 for temporary applications

and 2.0 for permanent applications.

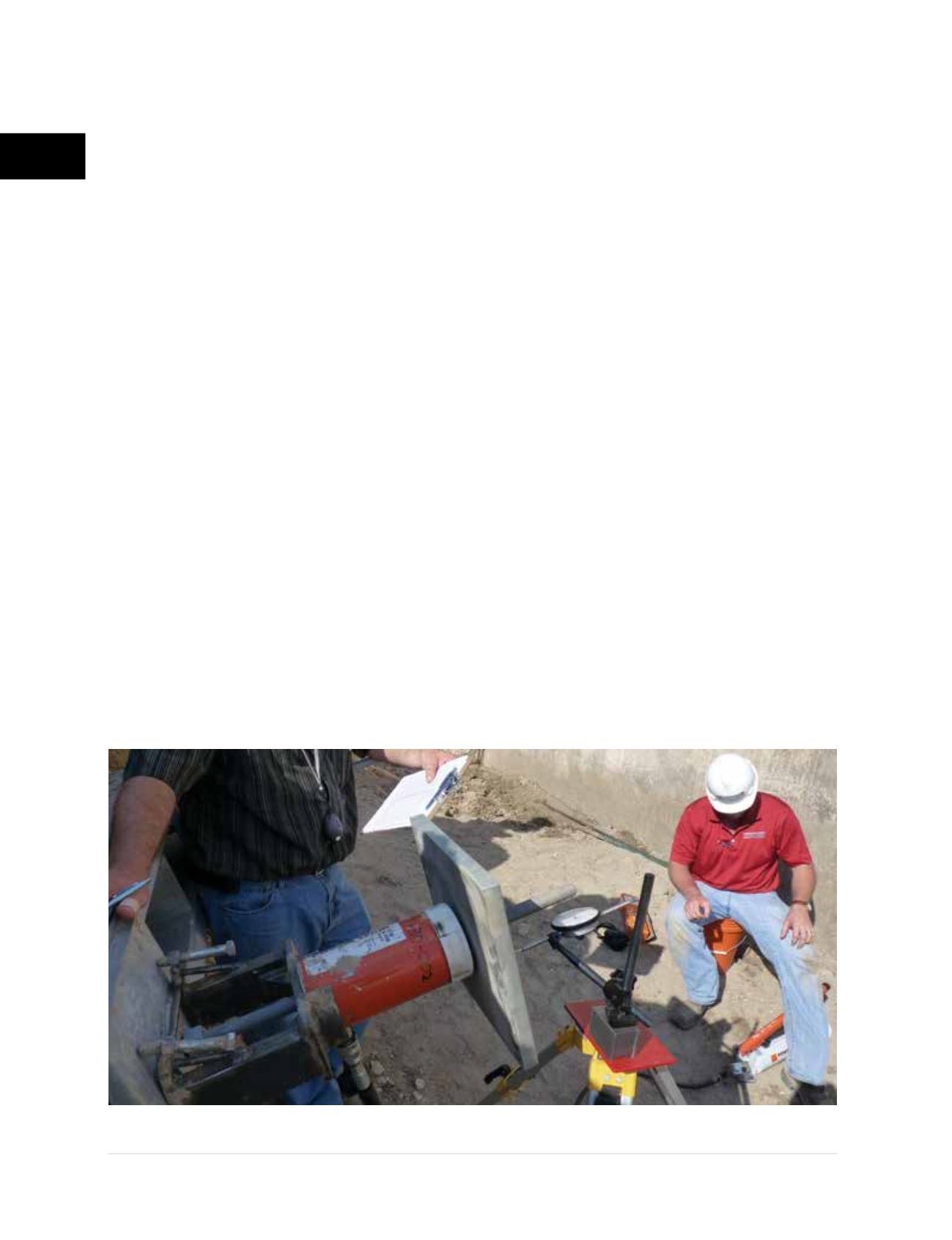

Foundation Supportworks recommends that

all helical anchors and tiebacks (excluding

soil nails) be pre-tensioned or proof-tested

following installation (Figure 2.8.1.c).

Pre-tensioning to 1.0 to 1.33 times the design

working load minimizes deflection of the

tiebacks and structure as the tiebacks are put

into service and the soil strength around the

helix plates is mobilized. Tiebacks installed

to support existing walls are typically locked

off at 0.75 to 1.1 times the design working

load after proof-testing. Helical anchors

and tiebacks to be cast into new concrete

retaining walls may be completely unloaded,

or locked off with a modest seating load, after

proof-testing. Tiebacks can be “pull tested”

or load tested to typically two (2) times the

design working load or more to identify the

ultimate system capacity, better assess soil

conditions and soil/anchor interaction, and

validate design assumptions and parameters.

Tiebacks that undergo load testing to

greater than 1.5 times the design working

load, or failure, are generally considered

sacrificial and should not be used as

production tiebacks.

Figure 2.8.1.c

Pre-tensioning helical tieback