© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 48

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

The followingmachine specifications are required:

• The machine should have a bi-directional

auxiliary circuit to power the drive head.

• Hydraulic fluid pressure output from the circuit

used to power the drive head should meet the

drive head specifications. On some machines,

it may be necessary to adjust the relief valve

on the machine’s auxiliary system hydraulic

pump to provide the appropriate pressure

specified by the drive head manufacturer.

• The flow rate of hydraulic fluid to the drive head

should meet the drive head specifications for

optimum performance during installation.

• The machine should have adequate weight to

resist torsional forces from the drive head and

to allow for proper crowd during installation.

FSI offers portable hand-held equipment for

operating smaller, lighter-weight drive heads

when access with machinery is not feasible.

The drive heads can be powered by auxiliary

hydraulic circuits of machinery or by portable

hydraulic power packs. The power source

should meet the operating specifications of the

drive head. A portable, remote valve assembly

allows for safe operation of the drive head when

used with the hand-held equipment.

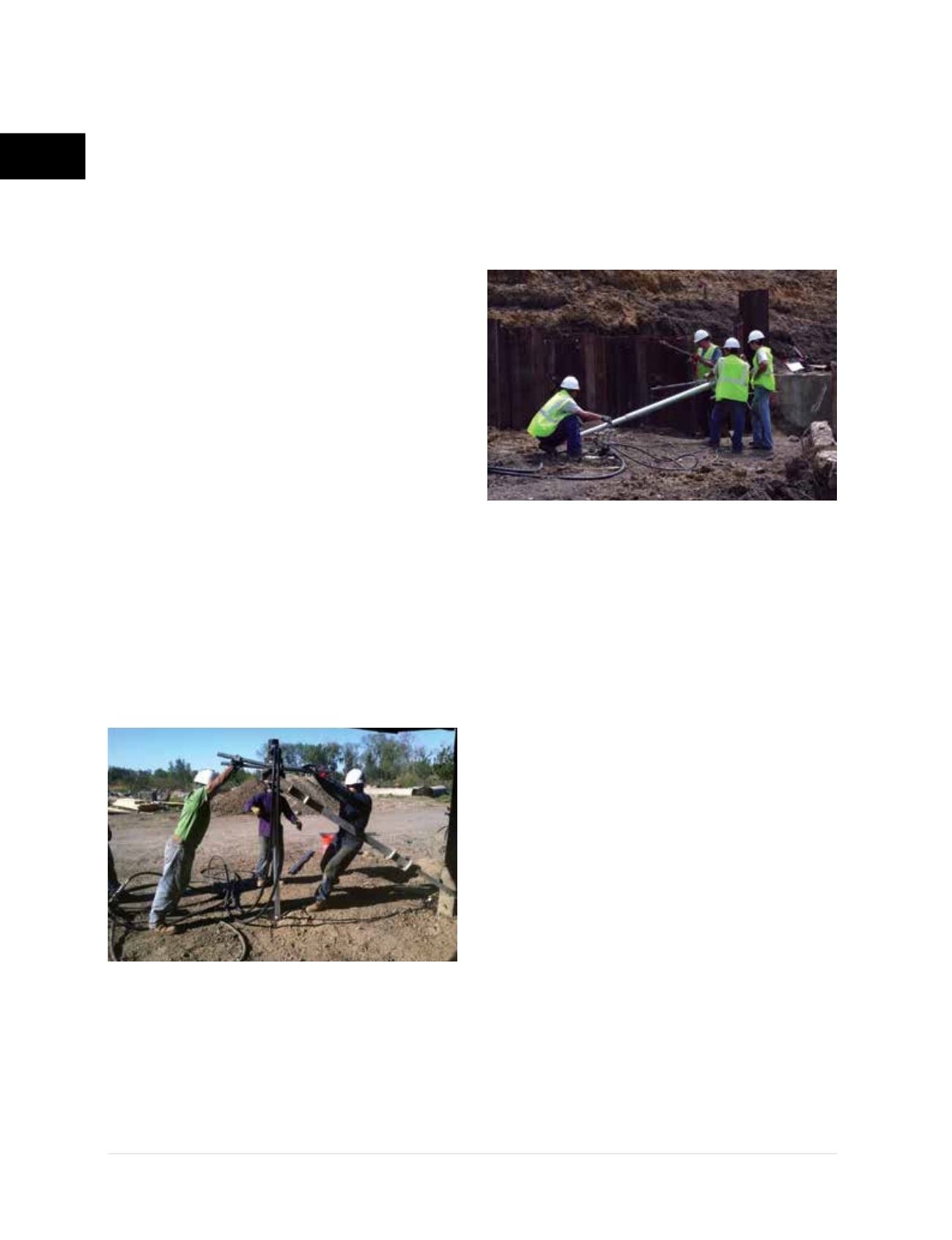

The drive head is mounted to the frame of the

hand-held equipment

(Figure 2.12.2.1.e)

so that it

can be supported and operated by at least two

technicians. To provide the reaction for the output

torque, a telescoping torque arm is attached to the

frame of the hand-held equipment. The torque arm

(Figure 2.12.2.1.f)

is secured against the ground, a

wall or other suitable structure or device capable

of resisting the torsional forces transferred to

the end of the torque arm by the drive head.

Hand-held equipment is typically limited to a

maximum installation torque of 6,000 ft-lb, or less.

Consult FSI with any questions regarding the rated

capacities of FSI hand-held equipment.

Installers and personnel in the immediate

work area should be properly trained in

the safe operation and use of hand-held

equipment. The torque arm shall be properly

restrained for the direction of arm rotation.

Reversing the rotation also requires

restraining of the torque arm in the opposite

direction. Personnel in the work area

should understand the direction that the

torque arm will tend to swing and position

themselves in a safe location (considering

any possibility that the torque arm could

break free from its restraint). Appropriate

installation geometry should be maintained

during pile installation. The ideal position for

the torque arm is as follows:

1) Arm is fully extended and is restrained at

its maximum radius from the pile shaft.

2) Arm is at an angle which is perpendicular

to the pile shaft.

Actual installation geometry is adjustable

and will vary, but in no circumstance shall the

torque arm be placed at an angle in excess

of 35 degrees from perpendicular and in no

circumstance shall the torque arm restraint

Figure 2.12.2.1.e

Hand-held equipment

Figure 2.12.2.1.f

Torque arm