© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 19

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

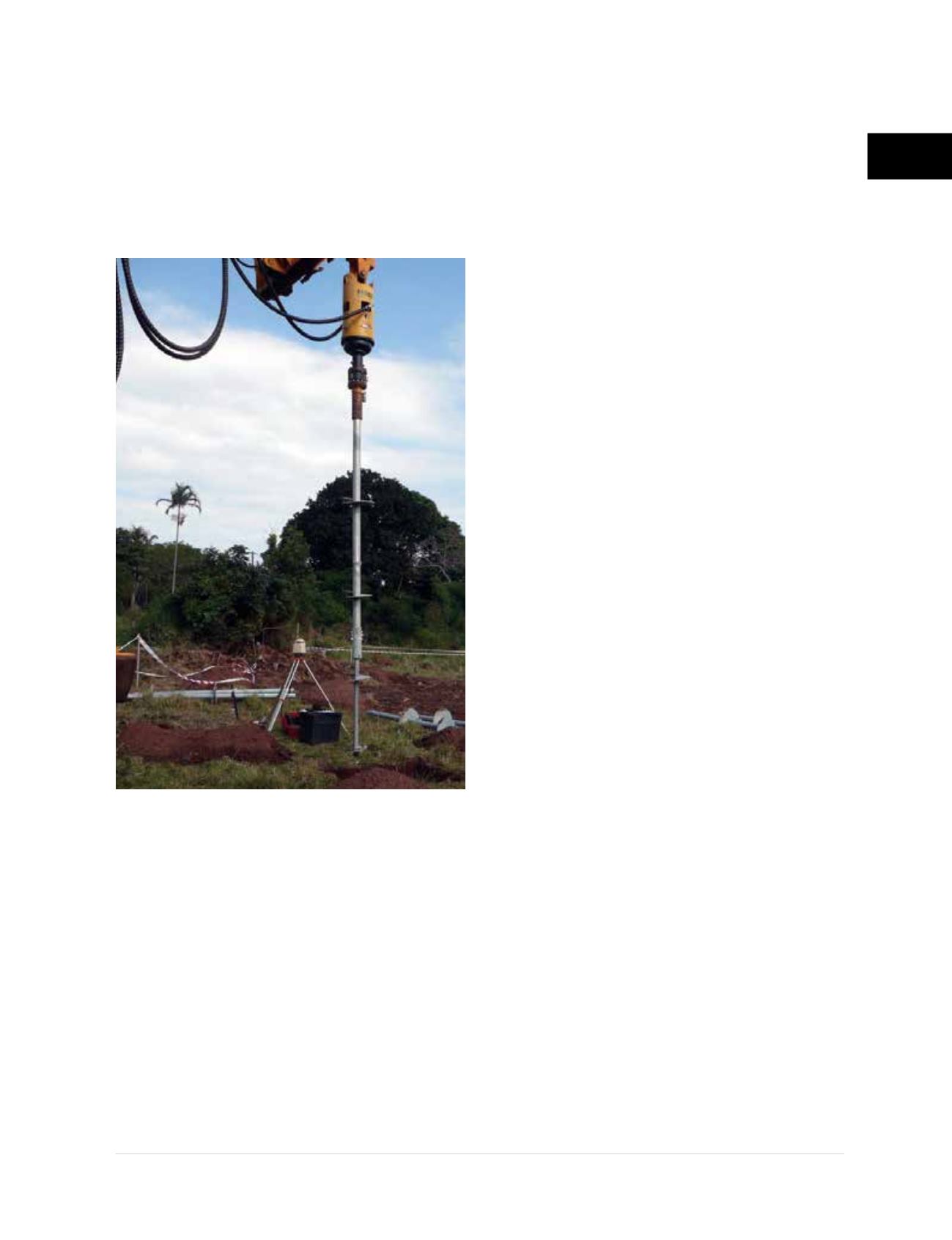

may also be considered to pass through or

penetrate into dense soil

(Figure 2.5.a)

. Where

large obstructions are encountered, the helical

piles may have to be offset from plan locations.

The project engineer should first be notified to

determine if other piles should be relocated or

if additional piles will be required.

• Helical piles will not typically penetrate hard

rock, defined by auger refusal by the drill

rig or Standard Penetration Test (SPT) blow

count values ≥ 50 blows/6 inches of sampler

penetration (ASTM D1586). Helical piles may

penetrate into hard clay, dense sand and soft or

weathered bedrock; however, larger installation

equipment is generally recommended to

provide “crowd” or axial force on the pile during

advancement into these soils. A square bar

stinger lead section may again be considered

along with the larger installation equipment.

• The slenderness of helical piles and their limited

exposed area to the surrounding soil does not

allow for generation of high lateral capacities.

In competent soils, allowable lateral capacities

may range from less than 1 kip to more than

5 kips for 2.875-inch to 3.5-inch O.D. round

shafts. Higher capacities may be achieved

as the central shaft size of the pile increases.

These capacities are typically achieved with

lateral deflections of one inch or more. Where

higher lateral loads are anticipated, or lower

deflection criteria required, lateral loads could

be resisted by (1) extending the structural

concrete grade beams or pile caps deeper to

take advantage of the passive resistance of

the soil, (2) incorporating battered helical piles

into the foundation design, (3) using structural

elements in the current design, such as floor

slabs with hairpin bars, or (4) incorporating

other structural elements to create fully-braced

conditions. Site-specific lateral load tests can

be completed to document the lateral capacity

to deflection relationship prior to installing

production piles.

Figure 2.5.a

Combination pile with HA175 stinger

coupled immediately to 3.5” O.D. shaft