© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 14

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

• Round shaft offers a higher lateral resistance

with more shaft area exposed to the

surrounding soil. If necessary, hollow round

shafts can also be grout-filled to further

improve the pile stiffness.

Solid square shaft helical piles do offer some

advantages over their round shaft counterparts.

• Square shaft is a more compact section than

comparably-sized round shafts and will therefore

achieve greater soil penetration for a given

amount of torque. This benefit is particularly

important in tieback applications where the piles

must be installed to certain embedment criteria

as well as torque/capacity criteria.

• Square shaft, again due to its more compact

shape, may penetrate through or into dense

soils or soft or weathered bedrock layers

more easily.

• Square shaft has less surface area exposed to

corrosion and corrosion can only occur from the

outside surface inward. Conversely, corrosion

is possible for round shaft on both the outside

and inside surfaces, although actually limited

on the inside surfaces of closed pipe sections

due to lack of oxygen. See Appendix 2E for

additional information on corrosion.

• The degree of shaft twist may be considered

as another rough indication of applied torque

since permanent deformation begins within

a known narrow range for each product.

Contractors know they have past this threshold

when the shaft twist is not recovered when

the installation torque is released.

Although

these observations can be used as a guide

or point of reference during installation,

FSI does not recommend that shaft twist

be used solely as a measure or estimate of

applied torque.

• Square shaft can withstand more deformation/

twist before shaft failure. Square shaft

is therefore much more forgiving during

installation, allowing less experienced

installers to decrease the applied torque

before shaft damage may occur.

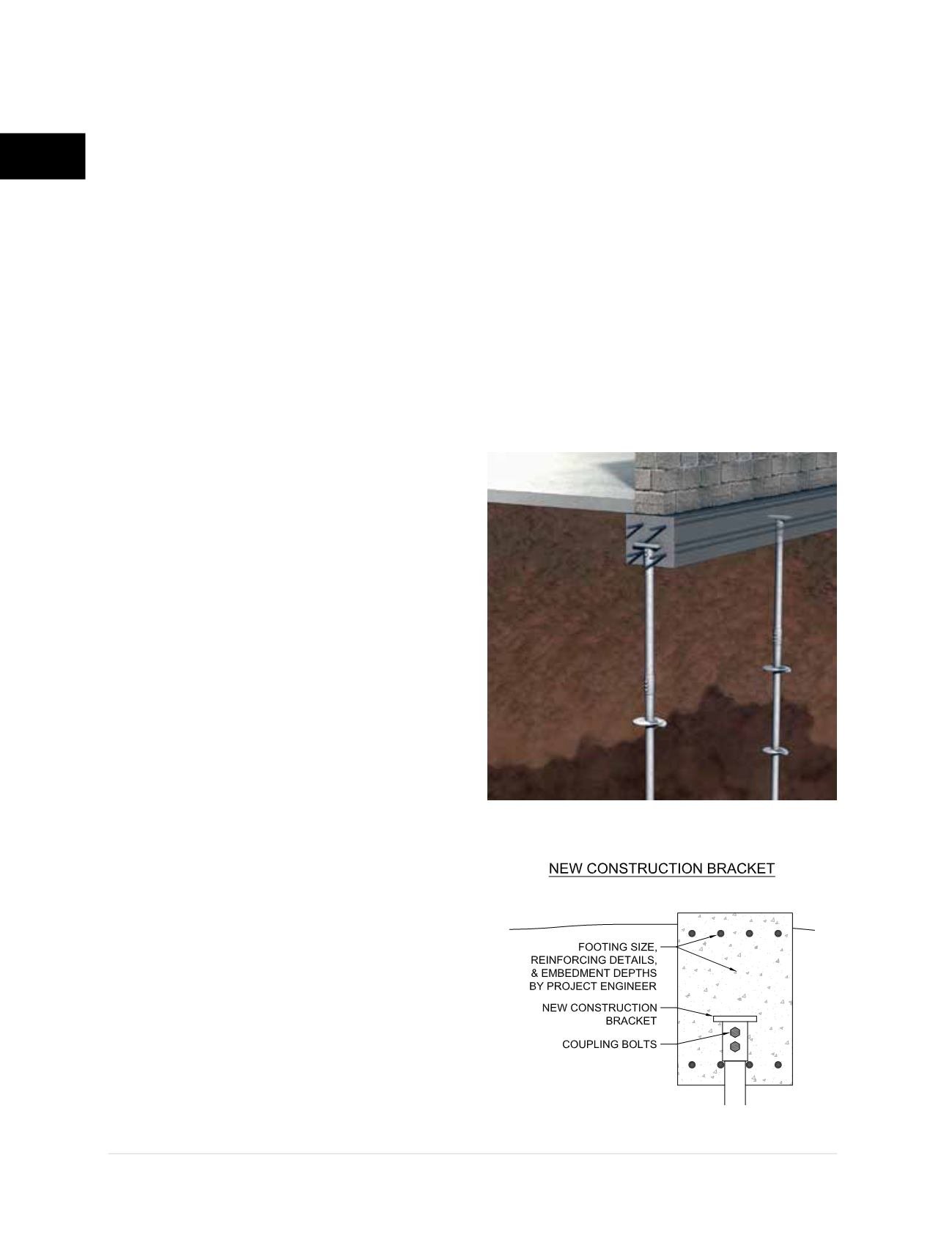

2.3.3 Brackets

A load transfer device (bracket) is used as a

mechanism to transfer the structural load to the

pile shaft. In

new construction

applications,

a bracket; i.e., cap plate or T-cap, is welded or

bolted to the top of the pile and then cast into

the structural concrete, into the grade beam or

pile cap. New construction brackets often consist

of round shaft sleeve material with a flat plate

welded to the top

(Figures 2.3.3.a1 and 2.3.3.a2)

.

Steel reinforcing bars may also be welded to the

sleeve or plate to further engage the concrete.

In compression load applications, the new

construction bracket could theoretically be set

on top of the pile without welding or bolting.

Figure 2.3.3.a1

Rendering of new construction

helical piles cast into a structural grade beam

Figure 2.3.3.a2

Schematic of new construction bracket