© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 16

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

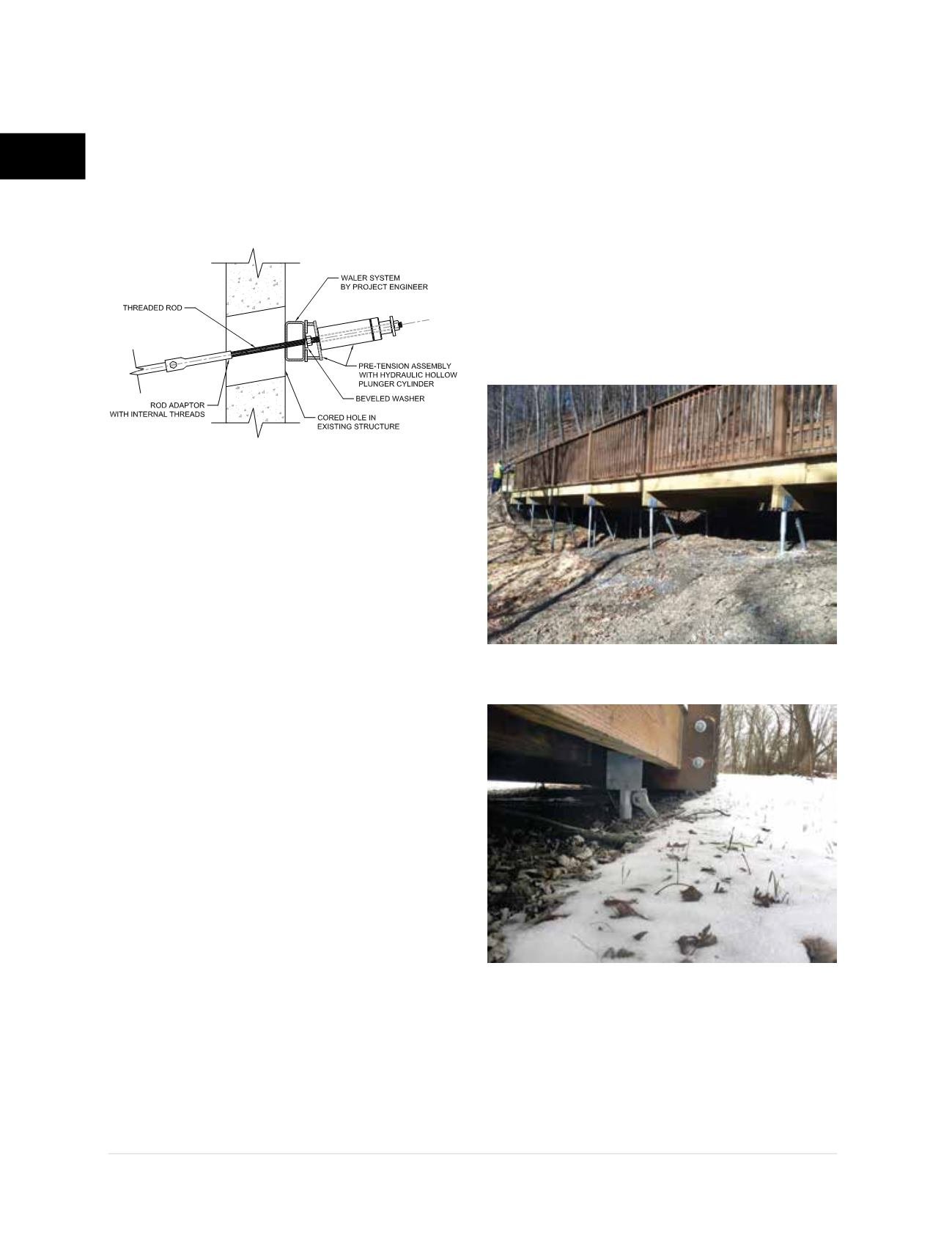

Plate brackets can be cast into the concrete of

a poured concrete wall or mounted to the face

of an existing concrete wall, sheet pile wall, or

soldier beam and lagging wall. Waler beams

may also be considered to more uniformly

spread the tieback or soil nail load to the wall

(Figure 2.3.3.d)

.

Foundation Supportworks recommends that

all helical anchors and tiebacks (excluding

soil nails) be pre-tensioned or proof-tested

following installation. Pre-tensioning to 1.0 to

1.33 times the design working load minimizes

deflection of the tiebacks and structure as

the tiebacks are put into service and the soil

strength around the helix plates is mobilized.

Tiebacks installed to support existing walls

are typically locked off at 0.75 to 1.1 times

the design working load after proof-testing.

Helical anchors and tiebacks to be cast

into new concrete retaining walls may be

completely unloaded, or locked off with a

modest seating load, after proof-testing.

Tiebacks can be “pull tested” or load tested

to typically two (2) times the design working

load or more to identify the ultimate system

capacity, better assess soil conditions and

soil/anchor interaction, and validate design

assumptions and parameters. Tiebacks that

undergo load testing to greater than 1.5

times the design working load, or failure, are

generally considered sacrificial and should

not be used as production tiebacks.

Specialty brackets may be required for certain

projects. Some of the more common specialty

brackets are often modified in their dimensions,

material properties, material thicknesses,

and/or connection details from project to

project due to variations in the design loading

and/or construction. Specialty brackets are

available for deck supports, boardwalk projects

(Figures 2.3.3.e1 and 2.3.3.e2)

, elevated

structures in high tide or hurricane-prone areas,

pipe buoyancy control, guy wires, tie downs,

etc. Contact FSI with any questions regarding

bracket details or availability.

Figure 2.3.3.d

Schematic of helical

tieback and pre-tension assembly

Figure 2.3.3.e1

Boardwalk supported on

2.375” O.D. vertical and battered helical piles

Figure 2.3.3.e2

Custom saddle bracket

connected with clevis to battered helical pile