© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 15

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

However, FSI still recommends that a positive

connection be made so the bracket is not lifted

or floated off the top of the pile during concrete

placement operations. Welding or bolting of the

bracket to the helical pile is required to resist

tension loads.

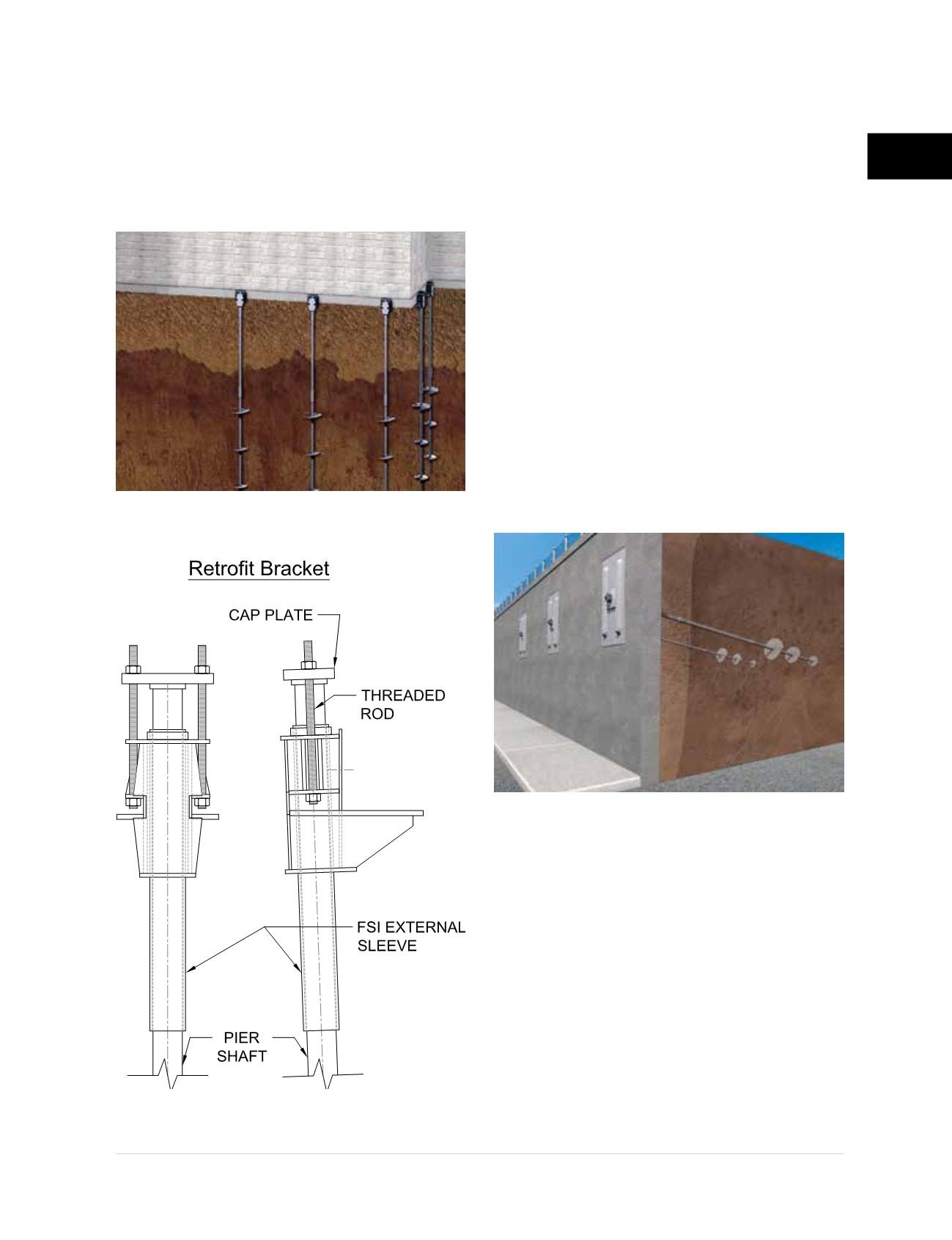

Retrofit brackets are used for

underpinning

existing structures

. These brackets are often

referred to as side-load or “L” brackets and are

typically designed to support the foundation

from below

(Figures 2.3.3.b1 and 2.3.3.b2)

. The

horizontal leg of the “L” is positioned below the

footing or foundation wall while the vertical leg

is positioned against the vertical face of the

footing or foundation wall. Footings that extend

beyond the face of the foundation wall are

typically notched-out at the bracket locations

to create a smooth, flat surface and so the

bracket is positioned as far as practical below

the wall. Helical piers with retrofit brackets are

often used to re-support existing structures that

have undergone settlement. These same retrofit

systems can be used to support additional

loads transferred to an existing structure due

to a building renovation or construction of an

adjacent addition.

Wall stabilization, earth retention, or

embankment stabilization

projects often

utilize helical tiebacks or helical soil nails as

system components

(Figure 2.3.3.c)

. Helical

tiebacks and helical soil nails may consist

of either hollow round shaft or solid square

shaft, although square is more common due

to its socket-and-pin style coupling (quick

connection) and the ability to penetrate further

into the soil with a similar amount of installation

torque than a comparably-sized round shaft.

The end of the shaft is typically fitted with an

adaptor to transition the shaft to threaded rod.

Figure 2.3.3.c

Rendering of helical tieback installation

Figure 2.3.3.b1

Rendering of retrofit helical piers

Figure 2.3.3.b2

Retrofit bracket detail