© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 8

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

force during the press operations are important

to ensure parallel leading and trailing edges and

the required pitch tolerances. The amount of die

press; i.e., the pressed shape and deflection, must

also be adjusted for changing plate thicknesses,

steel grades and anticipated spring back.

ICC-ES AC358 establishes design and testing

criteria for helical piles evaluated in accordance

with the International Building Code. AC358

provides the following criteria for helix plates in

order to be considered as a “conforming system”.

• True helix shaped plates that are normal with

the shaft such that the leading and trailing

edges are within

¼

inch of parallel.

• Helix plate diameters may be between 8 and

14 inches with thicknesses between

3/8

inch

and

½

inch.

• Helix plates and shafts are smooth and absent

of irregularities that extend more than

1/16

inch from the surface excluding connection

hardware and fittings.

• Helix spacing along the shaft shall be between

2.4 to 3.6 times the helix diameter.

• The helix pitch is 3 inches ±

¼

inch.

• All helix plates have the same pitch.

• Helical plates are arranged such that they

theoretically track the same path as the

leading helix.

• For shafts with multiple helices, the smallest

diameter helix shall be mounted to the leading

end of the shaft with progressively larger

diameter helices above.

• Helical foundation shaft advancement equals

or exceeds 85% of helix pitch revolution at

time of final torque measurement.

• Helix plates have generally circular edge

geometry.

Non-conforming systems may also seek an

ICC-ES product evaluation, but must undergo

additional product testing.

Foundation Supportworks’ helical piles feature

platesmanufacturedwithahelixshapeconforming

to the geometry criteria of ICC-ES AC358.

Conversely, plates that are not a helix shape are

often formed to a “duckbill” appearance. These

plates create a great deal of soil disturbance, do

not conform to the helix geometry requirements

of ICC-ES AC358, and their torque to capacity

relationships are not well documented.

The helix plate diameter, thickness and cut are

selected based upon the soil and load conditions

for the project. FSI currently offers:

• Helix plate diameters ranging from 6 inches to

16 inches

• Helix plate thicknesses of

5/16

inch,

3/8

inch, and

½

inch

• Plate steel yield strengths of at least 50 ksi

(Grade 50).

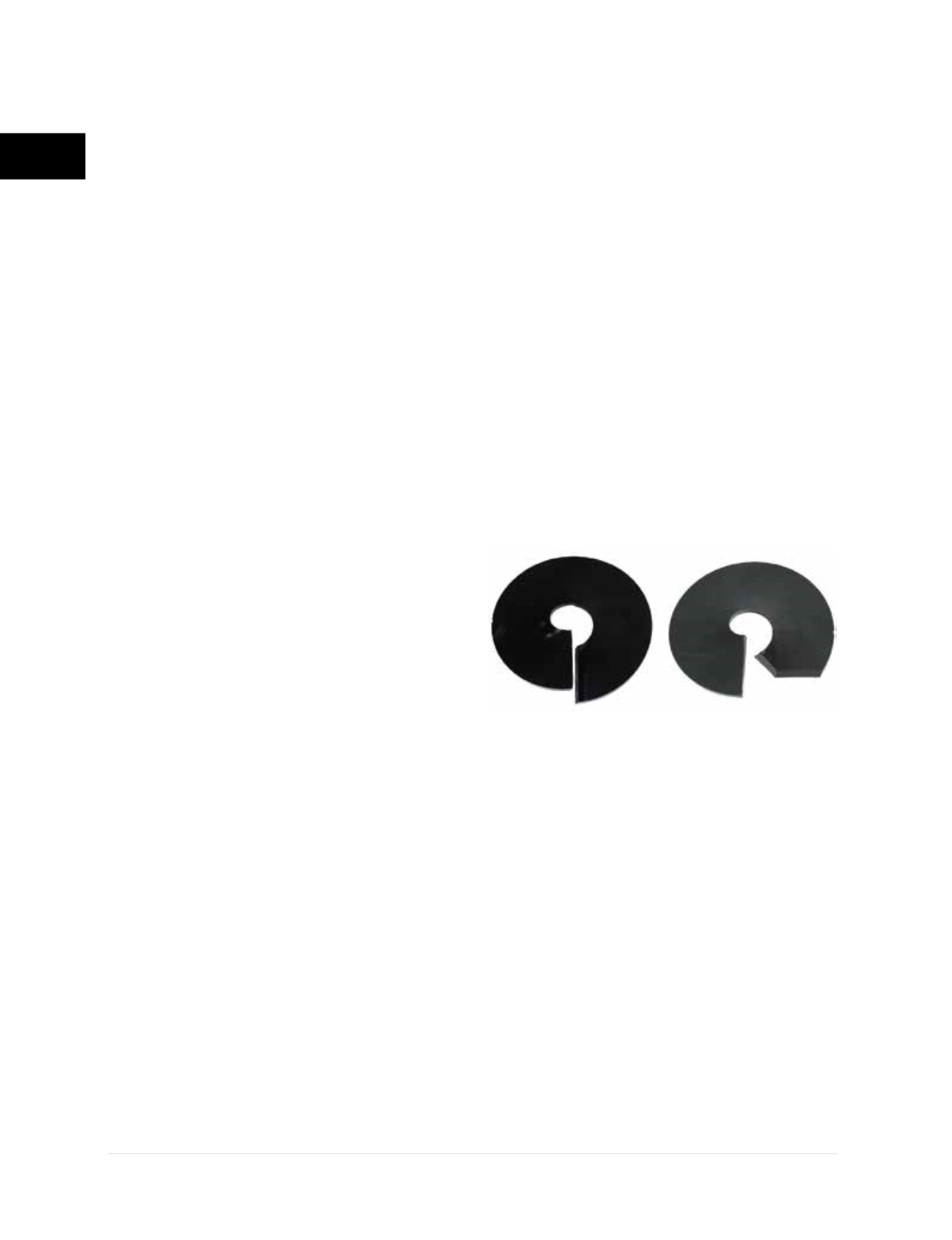

• Standard H-style cut and V-style cut plates

(Figure 2.3.1.c)

. V-style plates are special

order to assist in penetrating dense or rocky

soils. The leading edges of all helix plates are

sharpened (cut) to a 45-degree angle.

Figure 2.3.1.c

Standard H-style and V-style plates