© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 9

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.3.2 Central Shaft

The central shaft of a helical pile typically

consists of either solid square bar or hollow

round sections of tube or pipe. The shaft size

is selected to (1) resist the torsional forces

applied during installation and (2) transfer

the axial loads applied by the structure down

to the helix plates and surrounding soils. The

central shaft of an installed helical pile is

comprised of a lead section and extensions.

The lead section includes a 45-degree bevel

cut tip and one or more helix plates welded

along its length. The 45-degree bevel cut tip

further assists with pile advancement and

penetration through the soil. Lead sections are

generally fabricated in 5, 7 and 10-foot lengths.

Extensions, which may include additional helix

plates to provide increased pile capacity in

weaker soil conditions, are used to advance

the pile to the design depth, length, and/or

until the desired torque is achieved. Extensions

are generally fabricated in 3, 5, 7 and 10-foot

lengths. Custom lead and extension lengths

up to about 20 feet may also be considered

to reduce or eliminate coupled connections,

thereby minimizing overall product costs and

improving installation efficiencies. Generally,

a large track excavator would be required to

provide the reach necessary to install these

longer sections.

2.3.2.1 Coupler Detail

The coupler detail is yet another extremely

important feature when considering helical piles

and when selecting or specifying a product

manufacturer. Manufacturers may advertise

that they carry the same or equivalent helical

shaft. However, shaft and coupler details are

not consistent between manufacturers and

these differences may not be readily apparent

by simply reviewing marketing brochures and

product capacity tables. Some manufacturers

rate their products based upon the capacities

of the gross section of the shaft, thereby

ignoring any limitations caused by the coupled

connections. For these “equivalent” products,

there can be dramatic differences in material

properties, tolerances, spacing of bolt holes,

oversize of bolt holes, general fit-up, weld

quality, etc.

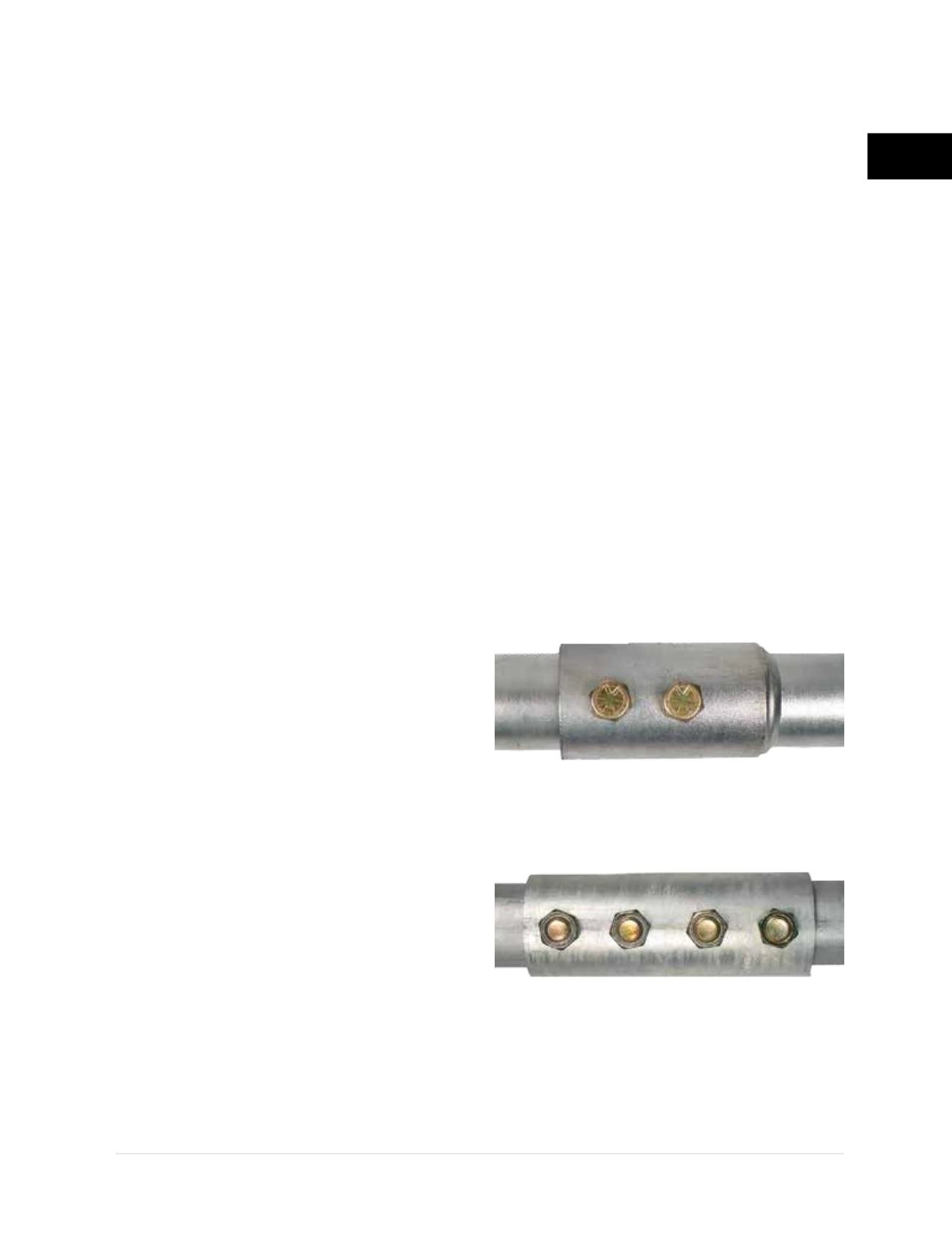

Some of the more common coupler details

for round shaft include external welded,

external detached, internal detached, and

forged and upset. External couplers utilize

tube or pipe sections with an internal diameter

slightly larger than the outside diameter of the

central shaft material

(Figures 2.3.2.1.a1 and

2.3.2.1.a2)

. These couplers can be sized to

provide tight connections that reduce angular

deformation and variances from straightness.

Such displacements at the couplers introduce

eccentricities to the system which can

significantly reduce the allowable compressive

capacity of the pile, especially considering

the slenderness of the more widely used shaft

material (typically 3.5-inch outside diameter

and smaller).

Internal detached couplers are made from solid

round stock or tube or pipe material but with an

outside diameter smaller than the inside diameter

of the central shaft material

(Figure 2.3.2.1.b)

.

Figure 2.3.2.1.a1

FSI external welded coupler

Figure 2.3.2.1.a2

FSI external detached coupler