© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 13

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

2.3.2.2 Round vs. Square

Solid square shaft helical piles have been used

successfully for decades in tension applications;

i.e., as anchors, tiebacks and soil nails, and

have proven to be a suitable and reliable support

alternative for such projects. Not surprisingly,

some manufacturers then adapted the use of

square shaft helical products to be installed

vertically for the support of compression loads.

There is much discussion amongst design

professionals and even professionals within

the helical pile industry about appropriate

applications for square and round shaft products.

With just a little understanding of the design and

manufacturing of these two systems, it quickly

becomes apparent for what applications the

products are better suited.

Square shaft helical piles have traditionally

been used in tension applications whereas

hollow round shaft piles have been used in

both tension and compression. In general,

FSI believes that hollow round shafts are

better suited for compression whereas solid

square shaft may provide some advantages

in certain tension applications. That said,

project parameters and site-specific soil

conditions vary, which may push the merits

and advantages of one system over the other,

and the design professional should select the

product best suited for the project. Please

contact the FSI Engineering Department with

any questions regarding product selection.

Hollow round shaft helical piles are particularly

suited to compression loading applications and

offer the following advantages over comparably-

sized square shaft piles.

• Round shaft helical piles, excluding those

with upset couplers, generally have more rigid

coupling connections. Square shaft helical

piles typically have a socket and pin coupling

which increases variances from straightness,

introduces eccentricity to the system, and

increases buckling potential. Refer back to

Figure 2.3.2.1.j

. Square shaft piles may be

considered for some light compression load

applications in soil profiles that offer sufficient

lateral support for these loads; e.g., Standard

Penetration Test (SPT) blow count values ≥

10 blows/foot (ASTM D1586).

• As stated in the Coupler Detail section, The

FSI round shaft helical piles are designed so

the pile shafts are in direct contact within the

coupling connections

(Figure 2.3.2.1.g)

. The

load path for round shaft piles in compression

is then directly through the shafts without

having to pass through the welds or bolts

at each coupling. Shaft to shaft contact

is more difficult to achieve within forged,

upset couplers. For square shaft piles, both

compression and tension loads are then

transferred through the one or two coupling

bolts in double shear.

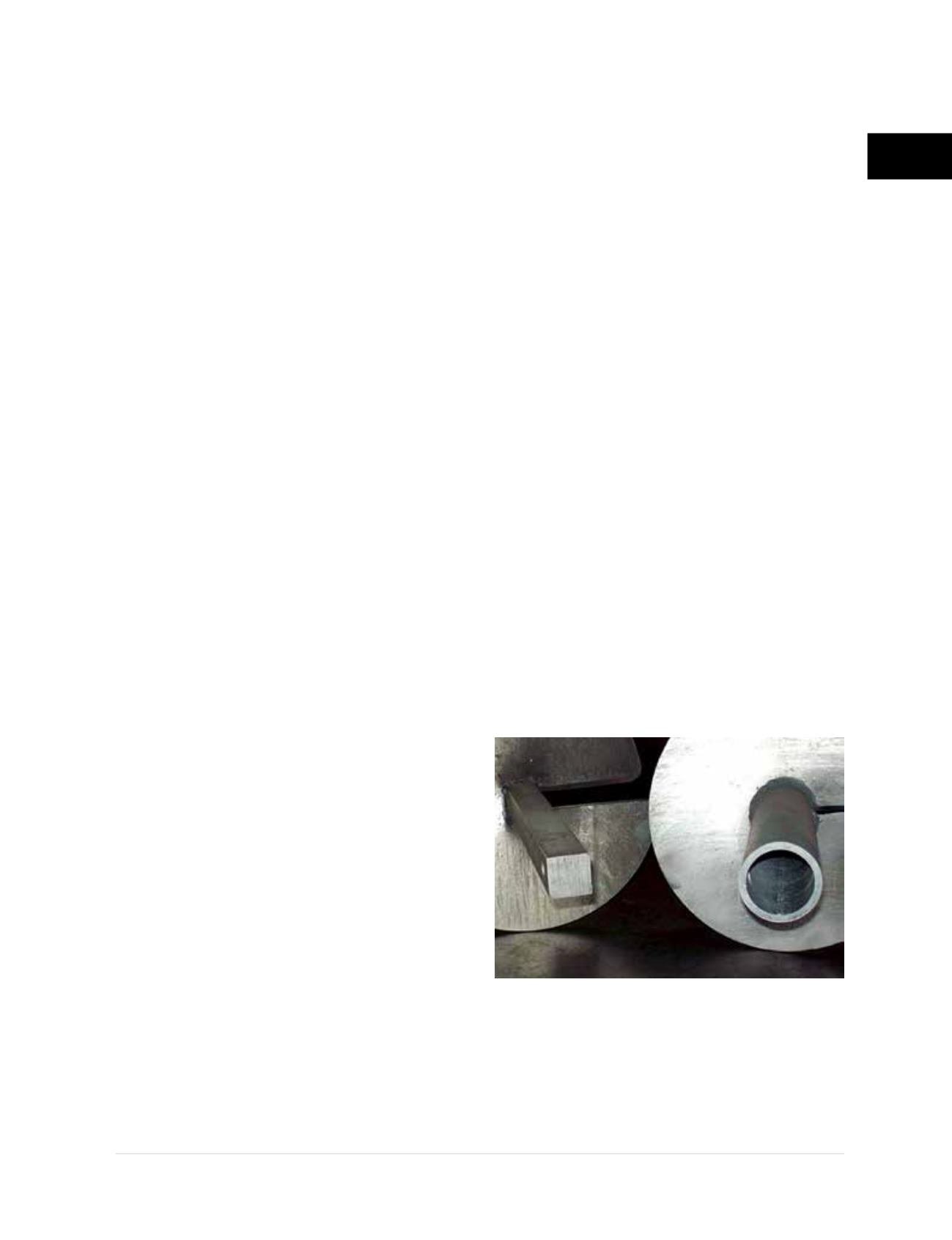

• The area of steel for a round shaft is located

outward from the centroid, thereby providing

a greater structural section modulus and a

higher moment of inertia. In layman’s terms,

a round shaft pile is more resistant to bending

(Figure 2.3.2.2.a)

. This is an important

consideration for piles with unsupported

lengths, piles penetrating loose or soft soils,

or for piles that are eccentrically loaded such

as in a retrofit application.

• Round shaft typically has a higher installation

torque rating than a comparably-sized square

shaft. For certain product comparisons, this

results in higher pile capacities.

Figure 2.3.2.2.a

Section comparison between 2.875”

diameter, 0.276” wall round shaft and 1.5” square shaft