© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 12

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

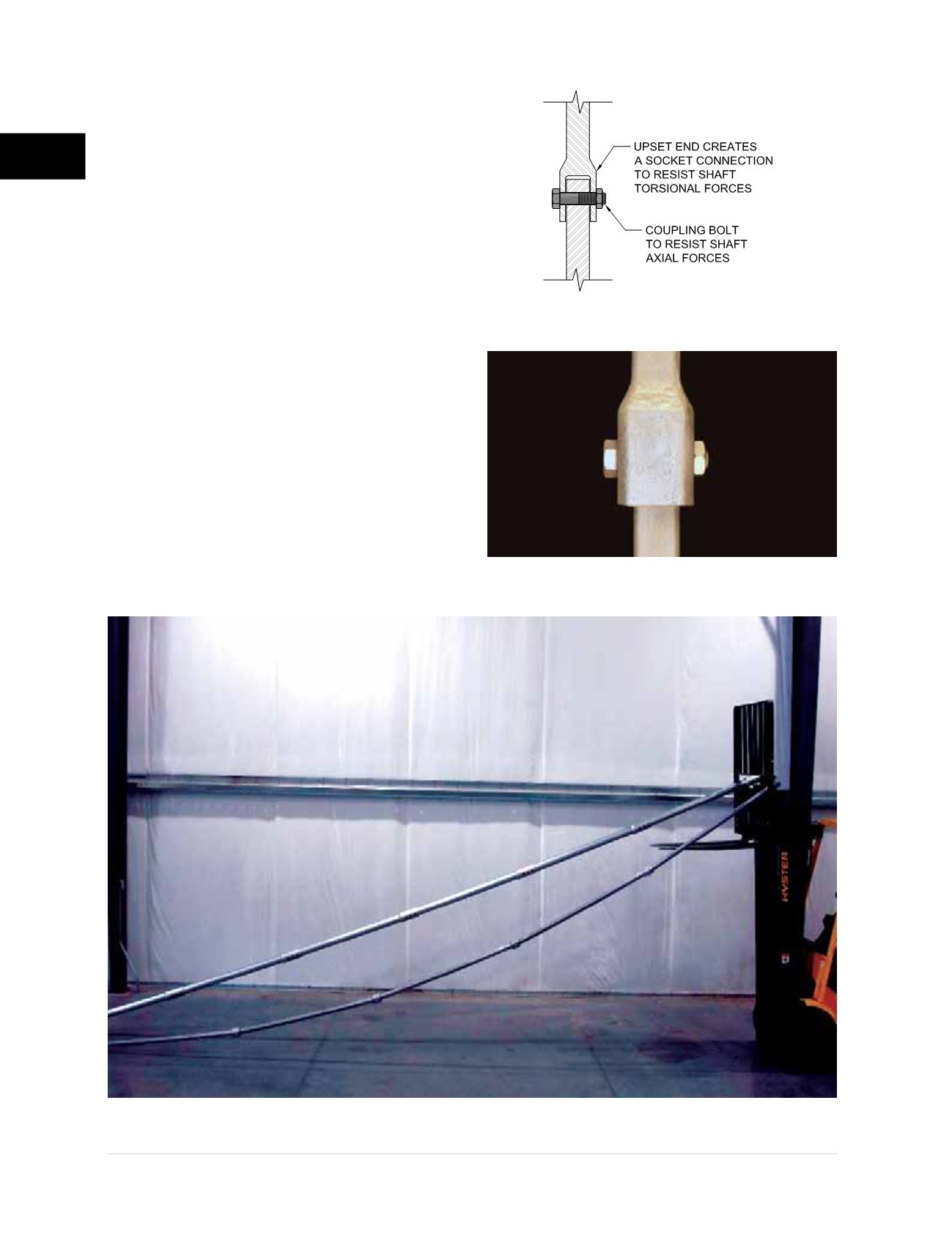

The most common coupler detail for solid

square shaft utilizes a forged and upset

end

(Figures 2.3.2.1.i1

and

2.3.2.1.i2)

. Cast

detached couplers and weldments have also

been used in lieu of the upsetting process.

The upset end of square shaft is created in a

similar manner as for the round shaft, except

for forming a square socket connection.

Figure 2.3.2.1.j

clearly shows a comparison of

coupling rigidity between an FSI external welder

coupler for round shaft and a typical upset coupler

for square shaft. A similar draping effect is typical

for round shaft helical piles with upset couplers.

FSI recommends that the design engineer

request product drawings and review coupling

details, tolerances and general fit-up prior to

product selection. As you have read in the

preceding paragraphs, seemingly equivalent

products may actually turn out to have very

different connection details, material properties

and capacities.

Figure 2.3.2.1.i1

Schematic of square

shaft forged and upset coupler

Figure 2.3.2.1.i2

Square shaft forged and upset coupler

Figure 2.3.2.1.j

Coupler Rigidity Comparison:

FSI round shaft external welded coupler vs. typical upset coupler for square shaft

Round Shaft

Square Shaft