© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 49

Chapter 2

Helical Foundation Systems

CHAPTER 2

HELICAL FOUNDATION SYSTEMS

be placed at a distance less than 7 feet from

the axis of the pile shaft. The capacity of the

hand-held equipment decreases significantly

when used outside of these parameters. The

force that will be required to restrain the

torque arm will also vary, but even within the

operation parameters just described, restraint

forces can approach 1,000 lb. The torque arm

restraint is therefore recommended to be

capable of resisting a force of at least 1,500 lb.

Lateral restraint is not only required at the end

of the torque arm. The drive head shall also be

restrained from lateral movement.

Drive heads used with hand-held installation

equipment should not be operated at speeds

exceeding 10 rpm. Operators shall be ready

at the controls and prepared to shut down

the equipment at any moment.

Failure to properly restrain and operate the

hand held installation equipment per these

guidelines can result in serious injury or death.

2.12.2.2 Installation Tooling

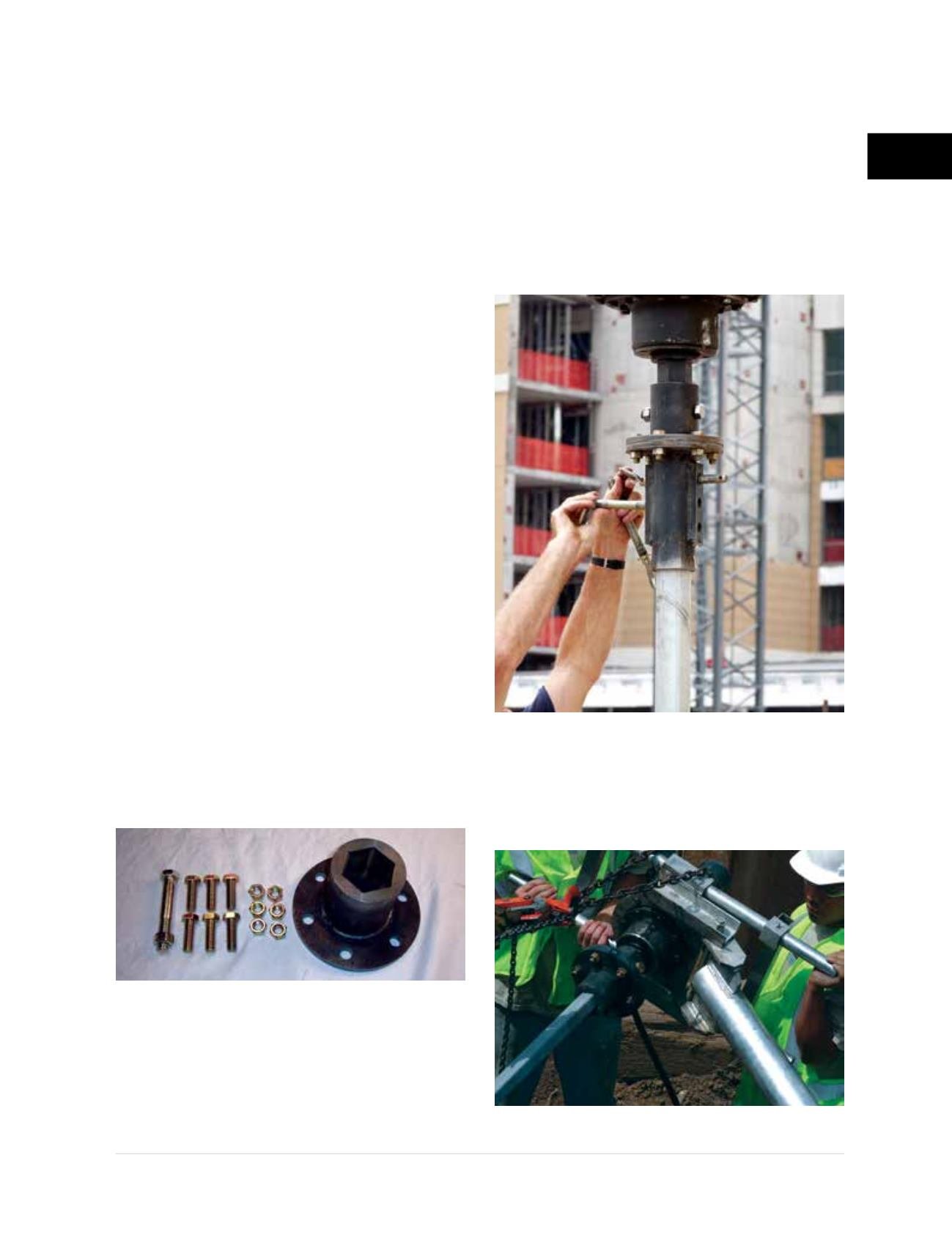

Installation tooling consists of the components that

are attached in-line between the drive head and the

helical pile, generally a hex adaptor and a product

adaptor. The drive head output shaft is typically a

hexagonal shape with measurements ranging from

2 inches to 3 inches across flats. The hex adaptor

slides over and is pinned to the output shaft of the

drive head

(Figure 2.12.2.2.a)

. The flange plate of the

hex adaptor has abolt holepatternwithhole spacing

and diameters to allow bolting to the appropriate

product adaptor for the dimensions of helical pile

shaft to be installed. Product adaptors are available

for the various sizes of hollow round shaft as well

as for solid square shaft. The ends of round shaft

helical piles generally slide into the product adaptors

and are connected with temporary hitch pins or

bolts for installation

(Figure 2.12.2.2.b)

. Solid-stock

internal product adaptors may also be used for

certain sizes of the round shaft helical product line.

The ends of square shaft helical piles and tiebacks

slide into a square, socket-like product adaptor

(Figure 2.12.2.2.c)

.

Installation tooling may also include an in-line

torque monitoring device as discussed in the

following section.

Figure 2.12.2.2.a

Hex adaptor

Figure 2.12.2.2.b

Round shaft product adaptor

Figure 2.12.2.2.c

Square shaft adaptor