© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 248

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

on the threaded rods to bring the main plate

and wing plates against the bottom of slab.

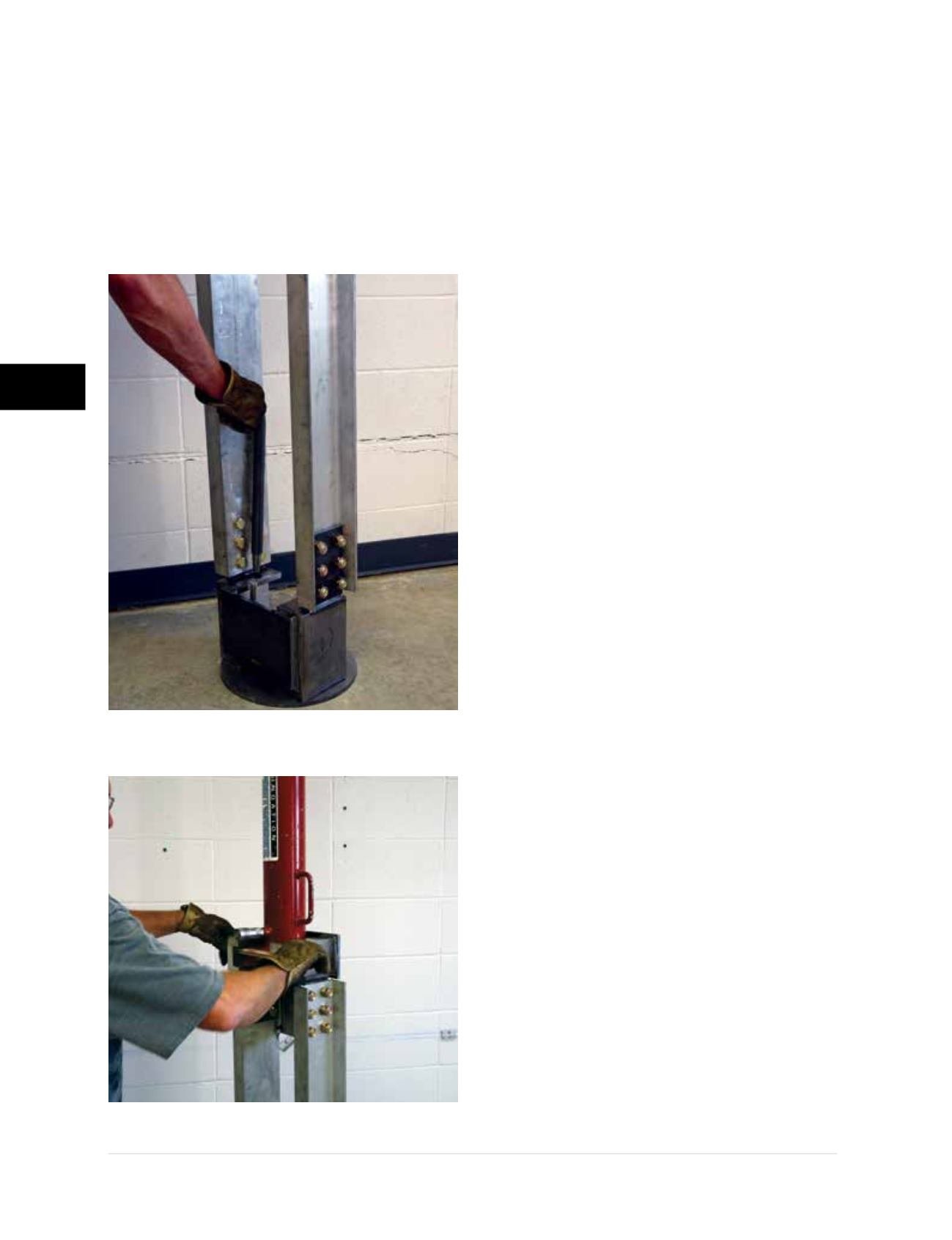

Slide the PP288 drive stand onto the slab pier

drive adaptor and secure with L-pins

(Figure

3.12.j)

. Set the hydraulic drive cylinder into

the top fixture of the drive stand and lock it

in position with the coil rod and nuts

(Figure

3.12.k)

. Connect the hydraulic hoses.

Step 4 Pier Tube Installation

• Electric pumps are preferred for slab pier

installations since the application of drive force is

moreeasily controlledand the riskof overstressing

the concrete slab during pier driving is reduced.

• Pier tubes are driven using similar procedures

as outlined in Section 3.10 (Step 4), including

recording of drive pressures at the end of each

driven tube. The drive stand should self-align

when force is applied by the drive cylinder to the

pier tubes; therefore, no cribbing or alignment

of the drive stand should be necessary if the

floor slab was prepared properly.

Safety precautions must be followed when

driving pier tube sections to ensure that

body and clothing are away from pinch

points. Take caution and avoid over-stroking

the cylinder rod which may result in a rapid

increase in pressure, possibly resulting in

cylinder damage or personal injury.

• Drive pier tubes until the required termination

drive force is achieved or slab movement

(flexing) in excess of about

¼

inch occurs. Care

should be taken by the installer to slowly release

hydraulic pressure at the end of each cylinder

stroke. Once the pre-determined termination

drive force is achieved or the slab starts to

lift, the pressure is released from the hydraulic

system and the drive stand and drive cylinder

are removed from the slab pier drive adaptor.

The drive adaptor is then disconnected from

the threaded rods of the slab pier bracket.

Figure 3.12.j

PP288 drive stand

mounted to slab pier drive adaptor

Figure 3.12.k

Drive cylinder set

into top fixture of drive stand