© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 245

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

3.11 PP288 Flush-Mount

Push Pier Installation

The PP288 flush-mount bracket system may be

used for applications where poured concrete

elements such as a foundation wall, column,

pile cap or grade beam have adequate strength,

thickness and vertical dimensions to allow proper

attachment of the bracket. PP288 flush-mount

system capacities are provided in Appendix 3A

for systems using either expansion or adhesive

anchors.

Step 1 Concrete Preparation

• Excavation may be necessary to expose the

vertical face of the concrete. If the bracket

is mounted on a foundation wall or column

above a spread footing, the concrete footing

would have to be cored through or removed

entirely to allow for advancement of the pier

tube sections. The vertical face of the concrete

to receive the bracket should be smooth of

surface irregularities and free of structural

cracks. A thin layer of leveling compound

could be considered to create a smooth flat

surface prior to mounting the bracket.

Safety precautionsmust be followed prior to

and during excavation. Locate underground

utilities prior to excavation activities and

perform excavations at a distance away

from utilities as mandated by the utility

owner. Follow OSHA guidelines for trench

safety during excavation and installation

activities.

Step 2 Mounting the Bracket

• The flush-mount bracket is secured to the

concrete vertical face using eight (8) -inch

diameter anchors. Rather than attempting

to position and hold the bracket in place, a

template of the bracket bolt holes could be

considered to mark the anchor locations.

Steps 3 - 7

• The remaining steps for flush-mount push

pier installation are similar to those for the

under-footing system described in Section 3.10.

3.12 PP288 Slab Push Pier

Installation

The PP288 slab push pier system is used to lift

and/or stabilize settling concrete floor slabs.

Monometer survey equipment, a laser level, a

zip level, or other suitable equipment should be

used to identify low areas in the slab. Slab piers

should be located at these identified low points.

Slab piers should also be considered either

centered on or on alternating sides of significant

floor cracks to ensure an even lift. Voids beneath

a stabilized and lifted slab should be filled with

suitable material such as a cement grout or

PolyLEVEL

®

polyurethane foam.

Step 1 Slab Preparation

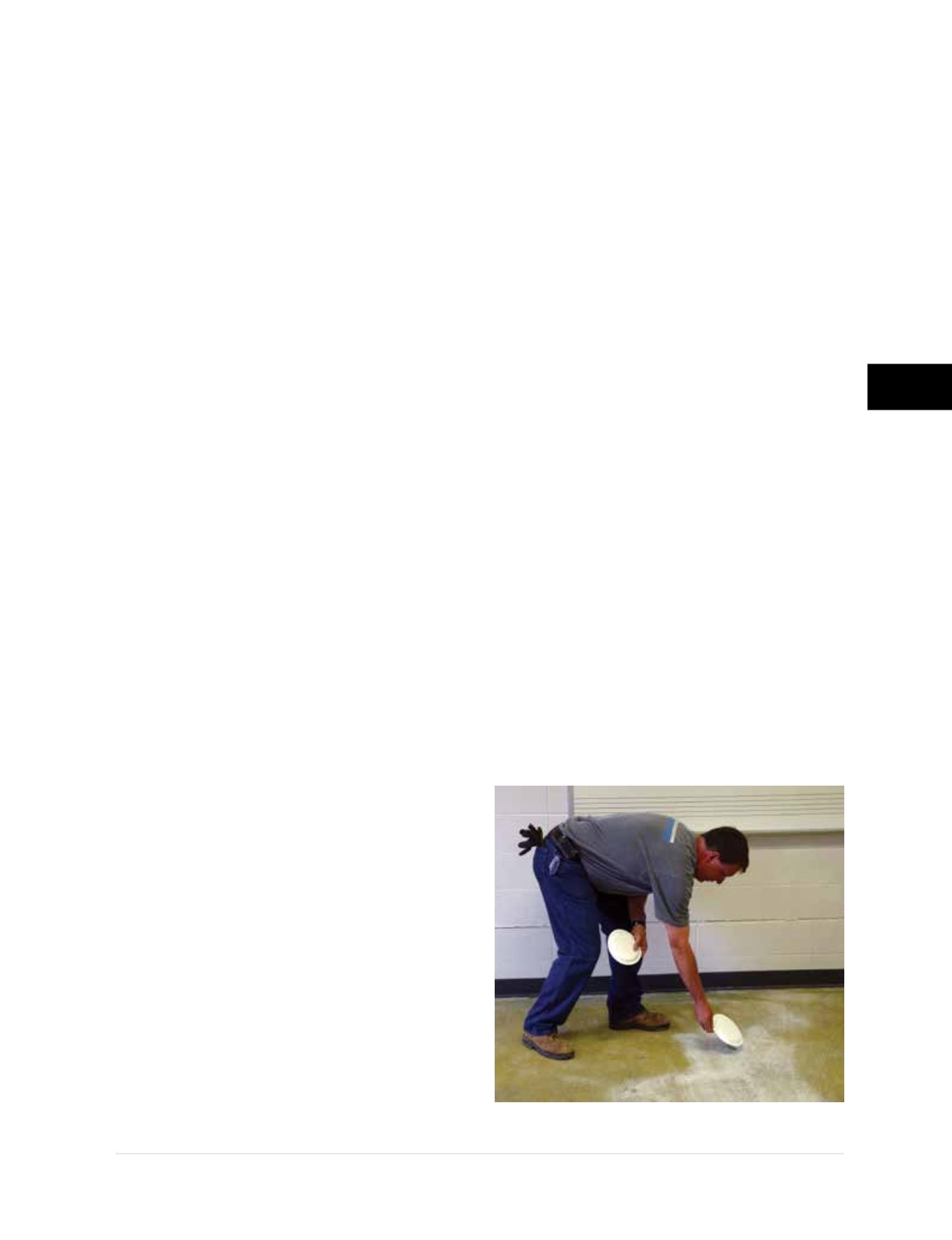

• Mark the slab pier locations with consideration

to possible underground utilities, overhead

obstructions, maximum pier spacing, existing

floor cracks and lift requirements. Small paper

plates may be used to mark preliminary slab

pier locations since the plates can be easily

moved around the slab

(Figure 3.12.a)

. Slab pier

Figure 3.12.a

Marking slab pier locations