© 2014 Foundation Supportworks

®

,

Inc.

All Rights Reserved

p 242

Chapter 3

Hydraulically-Driven Push Piers

CHAPTER 3

HYDRAULICALLY-DRIVEN PUSH PIERS

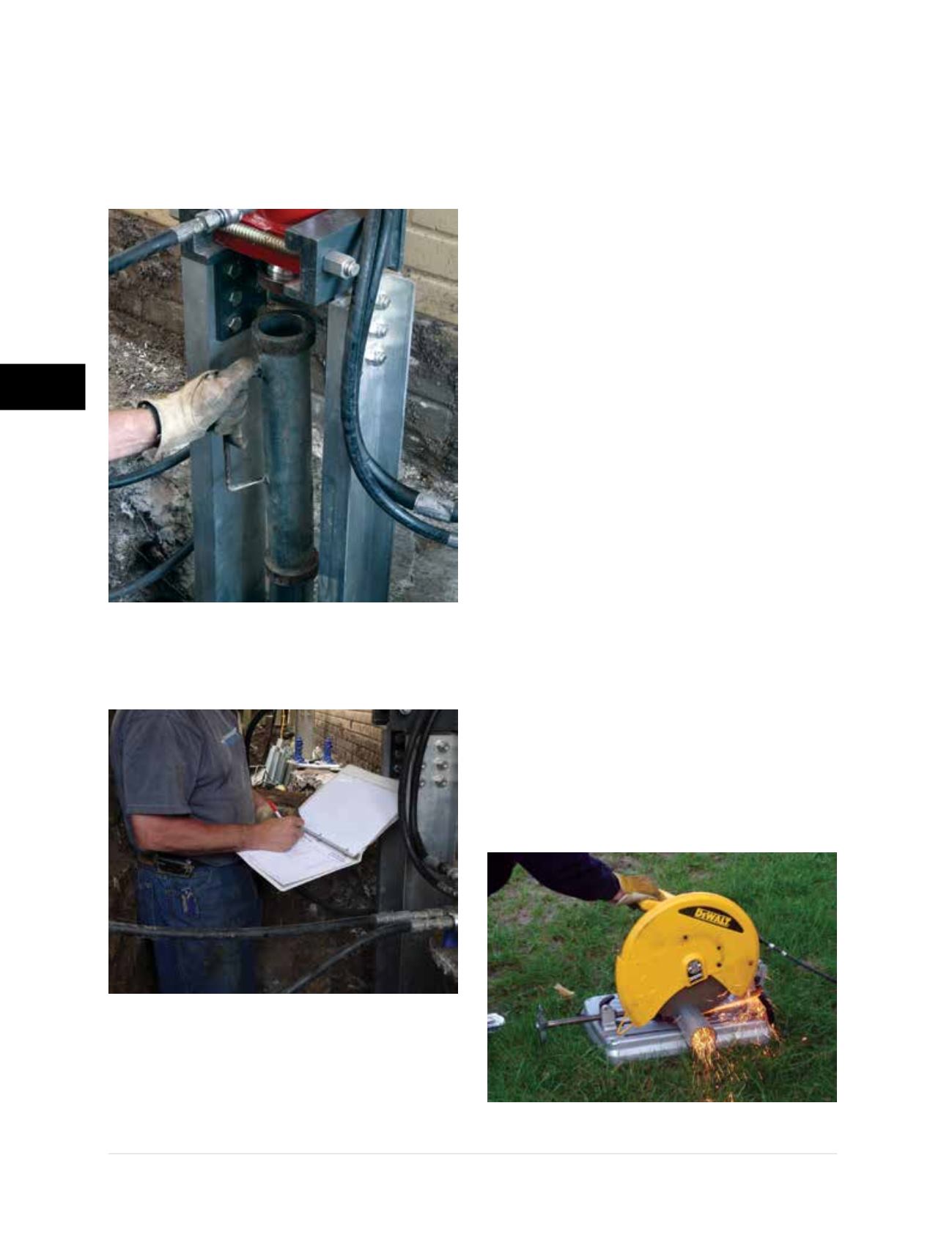

of a driving tube tool. When the maximum

cylinder stroke has been reached, the cylinder

is retracted, the drive tube tool is set in place,

and the push is completed to the top of the

bracket or external sleeve

(Figure 3.10.k)

.

• Record the drive pressure at final stroke of

each pier tube section

(Figure 3.10.m)

.

Safety precautions must be followed when

driving pier tube sections to ensure that

body and clothing are away from pinch

points. Take caution and avoid over-stroking

the cylinder rod which may result in a rapid

increase in pressure, possibly resulting in

cylinder damage or personal injury.

• Once the pre-determined drive pressure is

achieved or the structure starts to lift, the

pressure is released from the hydraulic system

and the drive stand and drive cylinder are

removed from the bracket. The drive process is

repeated at each of the proposed pier locations.

Step 5 Assembling the Bracket and

Mounting Lift Cylinders

• The final pier tube extending up from the

bracket will often have to be cut to the desired

elevation. FSI push pier systems with an

external sleeve offer a tremendous benefit over

systems without external sleeves. The final

pier tube is protected from bending and the

high pinching forces common between short

brackets and push pier tubes. The final pier tube

is then easily removed from within the external

sleeve and placed in a chop saw to achieve

a square cut

(Figure 3.10.n)

. Alternatively, a

tube cutting guide can be positioned over the

in-place pier section and a cut can be made

with a reciprocating saw or portable band saw.

The last pier tube section is typically cut to a

length to extend above the external sleeve

approximately 4

½

inches. The cutoff length may

vary depending upon the amount of structural

lift anticipated. The removed pier section is

replaced after the cut is made.

Figure 3.10.m

Pressure readings

are recorded for each pier tube

Figure 3.10.n

Cutting pier tube to

desired length with a chop saw

Figure 3.10.k

Driving tube tool set

in place for second stage of push